Introduction: Why 30% of B2B Orders Get Stuck

Imagine your warehouse is perfectly organized, your logistics partners are ready, and your ERP system is running smoothly. Yet customers complain about incorrect deliveries, sales teams spend hours on follow-up inquiries, and return rates eat away at your margins. What's going wrong?

The answer is often painfully simple: The error didn't happen during fulfillment—it happened during the order.

In the traditional view of order fulfillment, companies focus almost exclusively on what happens after the 'Buy' button is clicked. But current data paints a different picture: according to Digital Commerce 360, one-third of all B2B orders are faulty, often because technical specifications were unclear or availability wasn't checked in real-time.

This guide for 2026 redefines order fulfillment. We look beyond the classic process chain from capture to invoice, illuminating how Intelligent Automation and AI-powered consultation front-load the process. True efficiency doesn't come from processing an incorrect order faster—it comes from ensuring only correct orders enter the system in the first place.

What Is Order Fulfillment? (Definition & Distinctions)

Before diving into optimization, we need to sharpen our terminology. Terms are often used interchangeably, even though they have different focal points.

Order fulfillment (German: Auftragsabwicklung) encompasses all administrative, physical, and informational processes necessary to complete a customer order from placement through payment receipt and aftercare. It's the link between customer desire and actual service delivery.

Distinctions: Order Processing vs Fulfillment

Many companies fail at optimization because they operate in silos. The following table helps clearly separate responsibilities and identify interfaces. According to IOSCM and Deck Commerce, understanding these distinctions is crucial for process optimization:

| Characteristic | Order Processing (Admin) | Order Fulfillment (Logistics) | Complete Order Management (End-to-End) |

|---|---|---|---|

| Focus | Administrative & Commercial | Physical & Logistical | Holistic (End-to-End) |

| Primary Task | Capture, Verification, Confirmation, Invoicing | Storage, Picking, Packing, Shipping | Coordination of all steps from inquiry to cash |

| Typical Tools | ERP, CRM, Accounting Software | WMS (Warehouse Management System), Shipping Software | ERP + WMS + Shop Systems + AI Agents |

| Goal | Correct data, Legal compliance | Speed, Delivery quality | Customer satisfaction (CX), Efficiency, Margin |

| Common Mistake | Manual data entry, Media breaks | Pick errors, Packaging waste | Lack of communication between Sales & Warehouse |

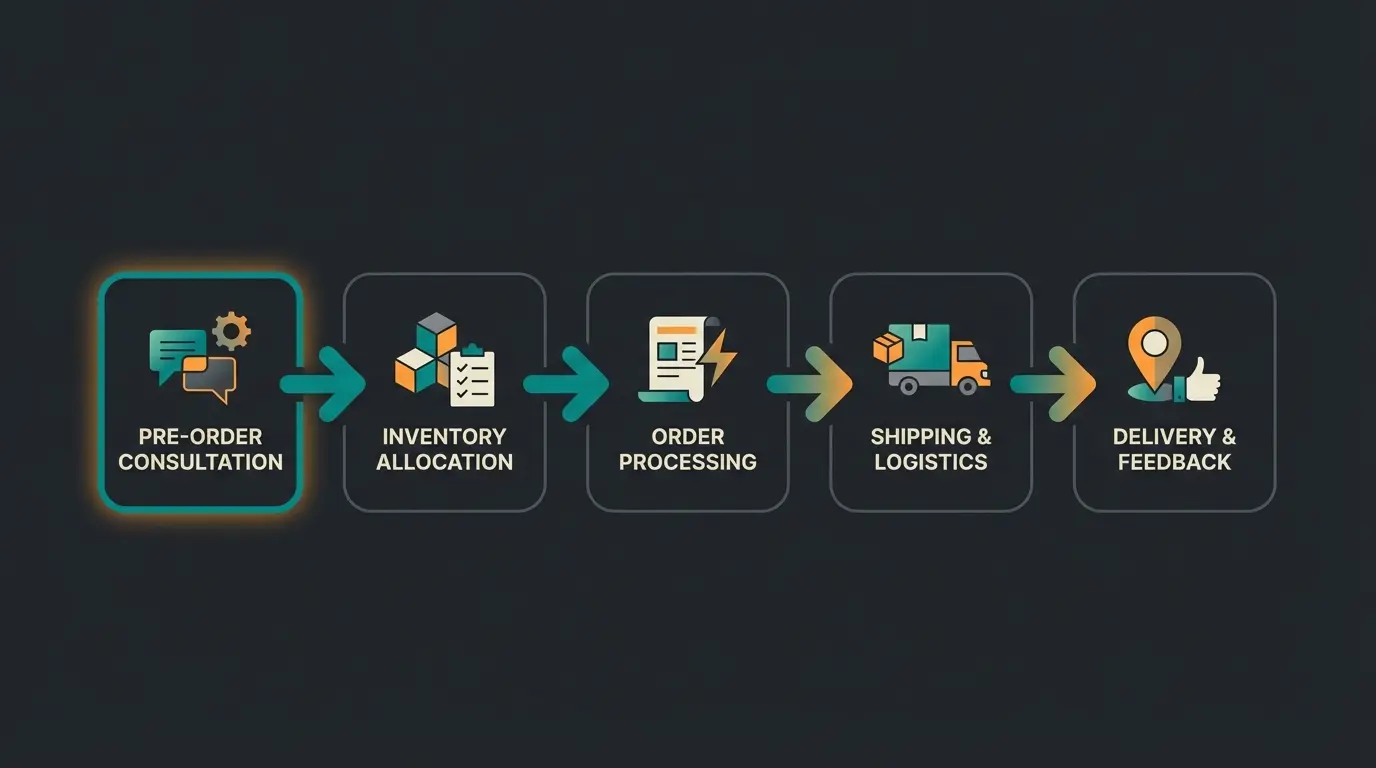

The Classic Order Fulfillment Process (5 Phases)

To optimize the process, you must first break it down into its components. While every company has individual nuances, order fulfillment typically follows a universal pattern of 5 to 8 steps.

Here's the standard process as found in most textbooks and ERP manuals—enriched with the critical points where things often go wrong in practice.

Customer inquires, configures products. Highest error risk through unclear requirements.

Data transfer to system, credit check, inventory verification, technical feasibility review.

Legal handshake with delivery dates and prices. Customer expects certainty here.

Pick lists, packaging, labeling, handover to carrier. High automation potential.

Invoice creation, payment monitoring, returns handling. E-invoice compliance required.

Phase 1: Offer & Consultation (Pre-Order)

This is often the neglected stepchild of order fulfillment.

- Activity: The customer gathers information, submits an inquiry, or configures a product.

- Status Quo: This often happens via email, phone, or static web forms.

- Risk: This is where most errors occur. If the customer orders Part A but needs Part B for their machine, the entire subsequent process is doomed to fail—no matter how efficient it is.

- Statistic: According to Sana Commerce, 68% of B2B buyers are discouraged by errors in this phase.

Phase 2: Order Capture & Verification

The order formally enters the company's system.

- Activity: Data transfer from the webshop, EDI (Electronic Data Interchange), or manual entry from email orders.

- Credit Check: Can the customer pay?

- Availability Check: Is the product in stock?

- Technical Verification: Do the components fit together? (Often done manually by engineers).

- Pain Point: Media breaks. When a PDF order must be manually typed into the ERP, error rates increase exponentially.

Phase 3: Order Confirmation

The legal handshake.

- Activity: The system sends a confirmation to the customer with delivery date and prices.

- Critical: This is the first point where the customer expects 'certainty.' Unclear delivery dates are a primary reason for customer churn according to Sana Commerce research.

Phase 4: Logistics (Picking & Shipping)

The order becomes physical.

- Activity: Creation of pick lists, retrieval of goods, packaging, labeling, and handover to courier/express/parcel service or freight forwarder.

- Trend: Automation levels here are already very high through WMS and scanners.

Phase 5: Invoicing & After-Sales (Post-Order)

The completion of the cycle.

- Activity: Invoice creation, payment receipt monitoring, and returns handling.

- Compliance Update: As of January 1, 2025, companies in Germany must be able to receive e-invoices; from 2027/2028, sending will gradually become mandatory in B2B according to IHK and Sage.

- Returns: If Phase 1 (consultation) was poor, costs explode here. Processing a return often costs more than the original shipment according to EHI research.

The Biggest Problems in Traditional Order Processing

Why does the machinery grind even though companies invest millions in ERP systems like SAP, Microsoft Dynamics, or weclapp? Analysis of the current market situation reveals three fundamental weaknesses that pure administrative software cannot solve.

1. The 'Garbage In, Garbage Out' Problem

ERP systems are excellent at processing data—provided the data is correct. However, if a customer orders the wrong spare part due to inadequate consultation, the ERP processes this error at blazing speed.

- Consequence: The wrong part gets perfectly packaged, delivered on time, and then expensively returned.

- Root Cause: Lack of validation of technical feasibility before order capture.

2. Media Breaks and Data Silos

Despite digitalization, many B2B orders are still placed via email (PDF attachment) or phone.

- Reality: A sales representative types data from a PDF into the ERP.

- Risk: Typos in article numbers or quantities.

- Silo Problem: Sales often doesn't know what's actually available in the warehouse because systems don't synchronize in real-time. According to Sana Commerce, 28% of buyers complain about inaccurate inventory displays.

3. Reactive Instead of Proactive Action

Classic systems wait for input. They only alert when an error has already occurred (e.g., 'Inventory level fallen below threshold').

- The Customer Suffers: They often learn days after ordering that delivery will be delayed.

- Expectations: B2B customers today expect Amazon-like transparency. According to Procurement Magazine, 40% of buyers cite unclear delivery dates as their main source of frustration.

One-third of all B2B online orders contain mistakes

B2B buyers would change for better order experience

Buyers frustrated by inaccurate stock information

Unclear dates as the main pain point for buyers

Optimizing Order Fulfillment: Why ERP Systems Aren't Enough

Here we come to the crucial point that sets you apart from your competitors. Most guides recommend for optimization: 'Buy a better ERP' or 'Automate invoice sending.' These are hygiene factors, no longer competitive advantages.

The real lever for optimization lies in the phase BEFORE the order.

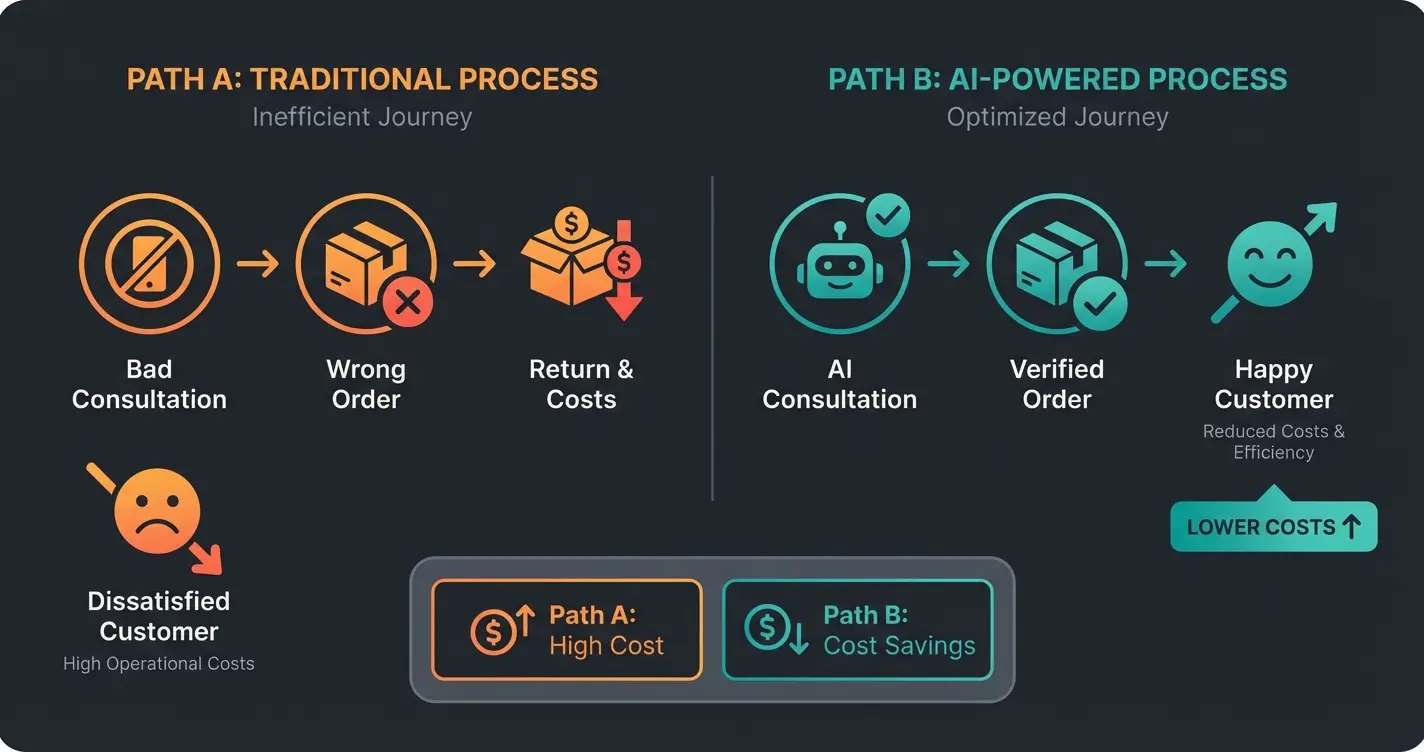

The Paradigm Shift: Intelligent Consultation

Instead of starting order fulfillment only when the order arrives, optimized fulfillment begins during the consultation conversation—supported by AI. As noted by Medium and CRM Software Blog, Agentic AI represents a fundamental shift from passive data processing to active problem prevention.

Comparison: Traditional vs. AI-Powered Approach

| Process Step | Traditional Approach (ERP Focus) | AI-Optimized Approach (Consultation Focus) |

|---|---|---|

| Customer Inquiry | Customer searches catalog, is unsure, orders 'on a hunch' | AI Agent analyzes customer needs in chat, checks technical spec compatibility |

| Order Receipt | Order arrives, is accepted unchecked | Order only permitted if data is valid & feasible ('Clean Data') |

| Follow-up Questions | Sales must call/email customer (ping-pong) | AI clarifies ambiguities in real-time during dialogue |

| Error Rate | High (due to incorrect orders) | Minimal (through preventive validation) |

| Returns | Managed as 'necessary evil' | Prevented through correct product selection |

The 'AI Shield' Concept

Don't think of your AI solution as a chatbot that only answers 'Where's my package?' Think of it as a shield in front of your ERP system. This shield only lets through orders that:

- Are technically plausible (Does Part A fit Machine B?)

- Are available (real-time check)

- Are completely configured

This massively relieves clerks from manual corrections and 'firefighting' actions.

Stop processing bad orders faster. Start preventing them entirely with intelligent pre-order consultation that validates every order before it enters your system.

Start Free TrialChecklist: Achieving Perfect Order Fulfillment

To elevate your order fulfillment to 2026 standards, you should audit and implement the following points. This list goes beyond standard logistics.

1. Enforce Digital Order Capture (Gently)

- Goal: Move away from email/phone toward structured data.

- Action: Offer customers incentives (e.g., 2% discount) when they order via portal/EDI instead of PDF.

- Tool: Use OCR AI to automatically read PDF orders if customers refuse to change.

2. Implement AI-Based Needs Analysis

- Goal: Return prevention through correct product selection.

- Action: Integrate a 'Technical Sales Agent' on your website that guides customers through complex configurations.

- Benefit: The customer feels consulted, not just 'processed.'

3. Synchronize Real-Time Inventory Data

- Goal: Create transparency.

- Action: Connect shop/sales frontend directly with WMS. No more nightly batch updates!

- Statistic: 46% of B2B buyers see real-time inventory as a 'must-have.'

4. Ensure E-Invoice Readiness

- Goal: Compliance and process acceleration.

- Action: Ensure your system can process ZUGFeRD 2.x and XRechnung formats.

- Deadline: Mandatory for B2B receipt since January 1, 2025. Use this as an opportunity to automate sending as well.

5. Proactive Status Updates (Track & Trace)

- Goal: Relieve customer service burden.

- Action: Automated push notifications for status changes (not just 'Shipped,' but also 'Delayed' or 'Partial delivery').

Future Trends: Agentic AI Instead of Just FAQ Bots

Looking to the future (2025-2030) shows we're on the threshold of a new era of automation. While we previously spoke of 'automation' (rule-based scripts: If A, then B), we now speak of Agentic AI.

What Is Agentic AI in Order Fulfillment?

Unlike passive tools or simple chatbots, AI agents can act. They have 'agency' (power to act), as explained by Kroolo and Rapidops.

- Example Today: A system reports: 'Delivery delayed.' The human must reschedule.

- Example Agentic AI: The agent recognizes the delay, checks alternative suppliers, autonomously books express delivery to meet the deadline, and informs the customer about the solution—the human only needs to approve (or not even that).

According to Logistics Viewpoints, these autonomous agents are transforming supply chain management.

Why Is This Relevant for You?

The market for Agentic AI in supply chain is growing rapidly (CAGR of over 14%) according to Mordor Intelligence. Companies that begin now to clean up their data foundation and train AI models on their products will have a massive speed advantage in a few years.

Agents can solve complex B2B scenarios, such as:

- 'I need the same part as 3 years ago, but in a heat-resistant variant.'

- The agent searches the history, reviews technical datasheets of new materials, and creates an offer—in seconds instead of days.

Frequently Asked Questions (FAQ)

Order fulfillment encompasses all steps from receiving a customer order to payment receipt. This includes: order capture, technical and commercial verification, order confirmation, warehouse management/picking, shipping, invoicing, and returns management. Modern definitions, however, start even earlier with quote consultation.

The greatest acceleration comes not from faster typing, but from error prevention. 1) Automated capture: Avoid manually typing orders. 2) Validation at entry: Use AI to immediately check orders for plausibility. 3) Interfaces: Ensure real-time data flow between webshop, ERP, and warehouse.

Order fulfillment is the umbrella term and includes administrative processes (credit checks, invoicing, customer service). Order processing (or order management) refers specifically to the logistical execution: storing, picking, packing, and shipping. Processing is therefore a subset of fulfillment.

In B2B, products are often more explanation-intensive, order quantities are higher, and customer relationships are longer-term. Additionally, there are individual price lists, framework contracts, and complex approval processes on the customer side. An error here weighs heavier because it can shut down entire production lines at the customer's site. Therefore, the quality of pre-consultation is much more critical here than in B2C e-commerce.

AI transforms order fulfillment from reactive processing to proactive prevention. AI agents can validate technical feasibility, check real-time inventory, guide customers through complex configurations, and even autonomously handle exceptions like delivery delays—all before human intervention is needed.

Conclusion: The Key Lies in the Start, Not the Finish

Optimizing order fulfillment has long been a topic for logistics and accounting. But in 2026, the game is decided earlier. Those who succeed in generating 'Clean Orders' through intelligent consultation and AI-powered validation solve logistics problems before they arise.

Don't just invest in faster conveyor belts or automated invoice bots. Invest in intelligence at your company's front door. Because perfect order fulfillment is one that never needs to be corrected in the first place.

Join forward-thinking B2B companies using AI-powered consultation to achieve perfect order fulfillment. Stop fixing problems—prevent them.

Get Started Free