Introduction: The End of Isolated Solutions

It usually starts gradually: the warehouse becomes unmanageable, the Excel spreadsheets for accounting crash, and the sales team sells products that are already reserved. In many companies, there's a 'chaos of separate pots.' Data sits in silos, and the CEO spends more time exporting CSV files than making strategic decisions.

At this point, you face the classic question: Inventory management vs ERP?

Most online guides make this too simple. They say: 'If you're small, get inventory management software. If you're big, get an ERP.' But this blanket logic is dangerous. A small e-commerce startup with 5 employees selling internationally often has more complex tax requirements than a local trade business with 50 employees.

As experts in data-driven process consulting, we see companies every day that are either suffocating in an overly rigid ERP or hitting growth limits with simple inventory management. In this article, we break down the differences—not based on marketing brochures, but on hard facts, current market trends for 2025, and real implementation data.

The Basics: Definitions and Core Functions

Before we dive deep, we need to clearly define the terms. This is crucial because many vendors use these terms interchangeably to enhance their product positioning.

What is Inventory Management Software (WMS)?

Inventory management software (often called Warehouse Management System or WMS) primarily focuses on the quantitative tracking of goods flow. It's the operational heart for retail and logistics operations, as explained by Haufe X360.

- Core Focus: Material flow (Purchasing → Warehouse → Sales)

- Main Functions: Inventory tracking, goods receipt/dispatch, ordering, delivery note creation, stocktaking

- Goal: Ensuring the right product is at the right place at the right time

- Analogy: Inventory management is the 'hands' of the company—it moves things

What is an ERP System?

An Enterprise Resource Planning (ERP) system takes a value-based and holistic approach. It doesn't just track goods flow but integrates all company resources (capital, personnel, equipment) in a central database. According to Xentral, this integration creates a 'Single Source of Truth' for all business data.

- Core Focus: Company-wide resource planning and control

- Main Functions: All inventory management functions plus financial accounting, controlling, HR, CRM, project management

- Goal: Creating a 'Single Source of Truth' for all company data

- Analogy: ERP is the 'brain and nervous system'—it connects all organs and controls the organism based on data

Direct Comparison: Inventory Management or ERP?

Many decision-makers are looking for a clear comparison. The following table compares not just functions, but also the strategic implications for 2025.

| Feature | Inventory Management (WMS) | ERP System | Best-of-Breed (Hybrid) |

|---|---|---|---|

| Primary Focus | Inventory & Logistics | Company-wide Control | Specialization per Department |

| Finance & Accounting | Usually just preparation (invoice output), export to accounting software | Integrated (Balance sheet, P&L, asset accounting, cost centers) | WMS + specialized finance software (via API) |

| CRM (Customers) | Basic data (address, history) | Deeply integrated (marketing campaigns, service tickets, sales pipeline) | WMS + Salesforce/HubSpot |

| Complexity | Low to Medium | High | Medium (complexity lies in the interfaces) |

| Implementation Time | 2-6 months | 6-18 months (or longer) | Incremental possible |

| Cost Structure | Lower license costs, often per user | High license and maintenance costs + high consulting effort | Sum of individual licenses (can be more expensive but more flexible) |

| AI Maturity (2025) | Often limited to inventory optimization | Comprehensive: cash flow forecasts, HR analytics, auto-disposition | High, as specialized tools are often innovation leaders |

| Ideal for... | Pure trading companies, startups, lean processes | Manufacturing, corporations, complex service providers | Digital scale-ups needing agility |

The Third Option: The Best-of-Breed Approach

Many articles ignore this option, but for modern companies, it's often the best solution. Instead of buying a massive ERP that does everything a little but nothing perfectly ('Best-of-Suite'), companies combine the best inventory management software on the market with the best financial software and the best CRM. This approach is gaining traction according to TimeChimp and Omniful.

- Advantage: You use specialist software that's often more innovative

- Disadvantage: You must ensure the interfaces (APIs) run stably. Data silos can emerge if integration fails, as noted by VersaCloud ERP

0-5 employees: Spreadsheets for tracking, manual data entry, disconnected systems

5-20 employees: Dedicated inventory management plus separate accounting software connection

20+ employees: Integrated enterprise system connecting all departments and processes

The 3 Biggest Misconceptions (Myth Check)

In our research and consulting, we constantly encounter myths that lead to expensive wrong decisions. Understanding the difference between inventory management and ERP requires dispelling these common misconceptions.

Myth 1: An ERP is Just a Big Inventory Management System

Wrong. The qualitative difference lies in financial accounting. Inventory management knows that 5 laptops are in the warehouse. An ERP knows that these 5 laptops have a balance sheet value of $5,000, are depreciated over 3 years, and are assigned to a specific cost center. As Passform Digital explains, when you search for 'inventory management or ERP,' the key question is often: Do you want to do your accounting in the system or at your accountant's office?

Myth 2: Small Businesses Never Need an ERP

Wrong. Company size (revenue/employees) is a poor indicator. A biotech startup with 10 employees that needs strict compliance rules, batch tracking, and investor reporting often needs ERP functionality from day one. Complexity drives ERP needs, not employee count, as highlighted by Gebra IT.

Myth 3: An ERP Will Solve My Process Problems

Dangerous. An ERP system forces you into standardized processes. If your current processes are bad, they'll just become 'faster bad' through an ERP. Implementing an ERP often requires complete re-engineering of work methods. Without process optimization before implementation, the project will fail. Both Passform Digital and Abas ERP emphasize this critical point.

When is the Switch Worth It? (The Trigger Points)

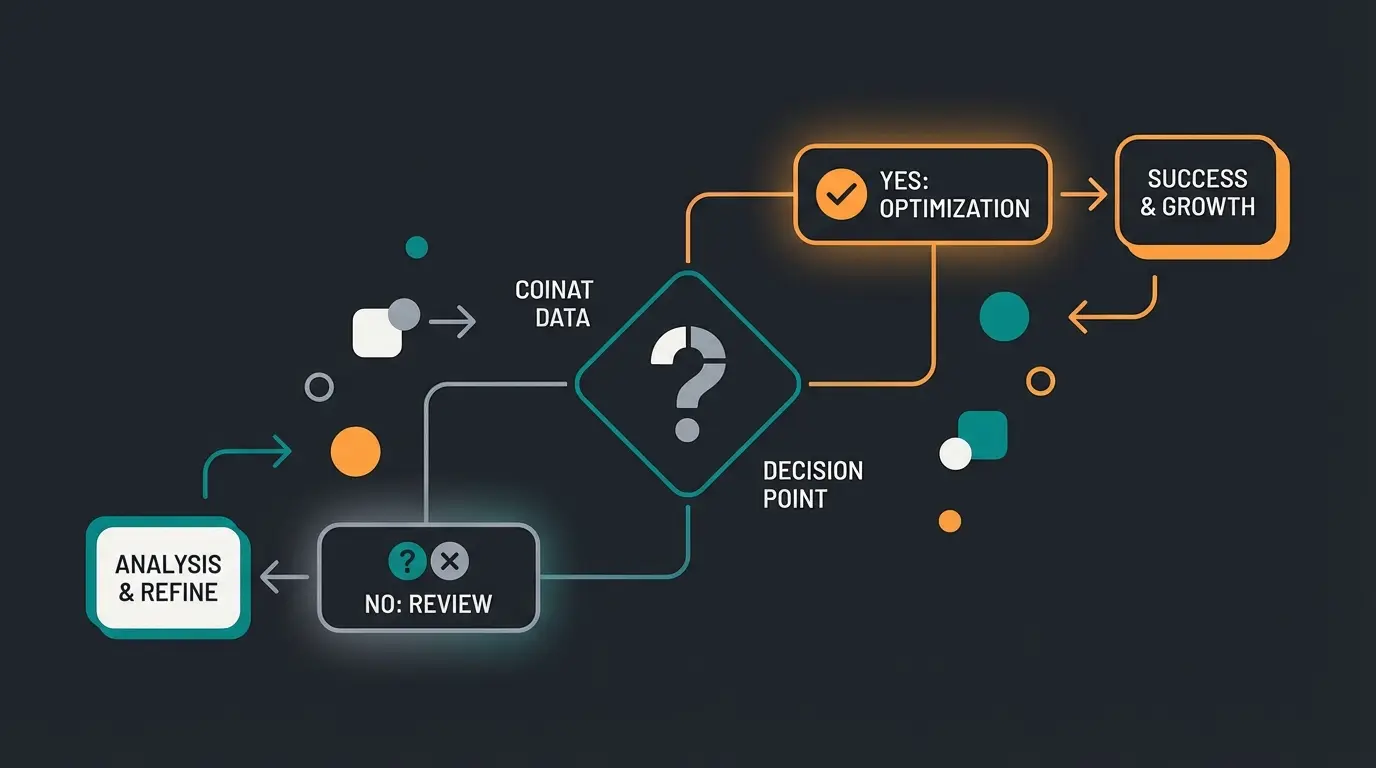

Don't wait for a 'gut feeling.' Analyze your company for the following hard trigger points. If more than two apply, your current inventory management solution is probably at its limit:

1. The 'Excel Hell' in Controlling

When you have to manually merge data from three different systems into Excel for the monthly closing just to know your margin, you've outgrown basic inventory management.

2. Internationalization & Multi-Entity

You're founding a subsidiary abroad or need to handle complex tax rules (VAT procedures, different currencies). Inventory management systems often fail at consolidating multiple companies (intercompany transactions), as SelectLine points out.

3. Media Breaks in Manufacturing

When you manufacture and the bills of materials (BOM) aren't automatically synchronized with purchasing and inventory. Simple inventory management often can't handle multi-stage production processes or extended workbenches.

4. Omnichannel Complexity

You no longer sell just in a store but on Amazon, eBay, Walmart, and your own Shopify store. If inventory reconciliation doesn't happen in real-time, you risk overselling. This is where older inventory management systems without modern API-first architecture hit their limits.

5. Compliance & Traceability

In industries like food or pharmaceuticals, you must track batches completely. An ERP often offers integrated quality management modules that simple inventory management lacks.

ERP projects that don't meet original goals according to Gartner research

Typical cost explosion compared to initial project estimates

Initial productivity decrease after go-live during adaptation phase

Stop guessing with generic advice. Our AI analyzes your specific data flows and processes to recommend the optimal solution—whether that's inventory management, ERP, or a hybrid approach.

Get Free AI AnalysisThe Role of AI in Selection and Usage (2025 Trend)

This is where the wheat separates from the chaff. In 2025, AI is no longer a gimmick but a competitive advantage. Your decision for a system should depend heavily on how well the vendor has integrated AI.

AI in Inventory Management: Intelligent Forecasting

Classic inventory management works with reorder points (min/max). When stock falls below 10, reorder. AI-powered systems (like those in modern supply chain modules) analyze historical data, weather trends, seasonal fluctuations, and marketing activities.

Use Case: The AI recognizes that due to a planned marketing campaign and the weather forecast, demand for Product X will increase by 40% and orders before the warehouse is empty. SelectLine highlights these predictive capabilities.

Impact: Reduction of inventory holding costs by up to 20-30% by avoiding 'slow movers' and stock-outs, according to analysis by Ahex Technologies.

AI in ERP: The Autonomous Copilot

Major vendors like Microsoft (Dynamics 365 Copilot) or SAP (Joule) are integrating generative AI deeply into processes. ERP Software Blog and Washington Frank document these developments extensively.

- Automation: AI can scan, assign, and post incoming invoices or detect anomalies in cash flow

- Interaction: Instead of configuring complex reports, ask the system in chat: 'What was the contribution margin of Product Group A compared to last year in the Southeast region?' and get an instant analysis, as Forbes reports

The Dark Side: Implementation and Risks

One aspect missing from sales brochures is the pain of transition. A switch from inventory management to ERP is comparable to 'open-heart surgery.'

The Statistics of Failure

Studies (including from Gartner) show alarming numbers, as documented by Rand Group:

- 55% to 75% of ERP projects don't achieve their original goals

- Cost explosion: Budgets are often exceeded by three to four times, according to Jacopo

- Timeline: Delays are the rule, not the exception

The Productivity Dip

After go-live, productivity doesn't immediately increase. On the contrary: it often drops by 10% to 15%, as The Change Compass documents. Employees must learn the new system, processes need to settle in.

- Strategy: Plan for this dip. Never start an ERP project during peak season (e.g., before Black Friday in retail)

- Solution: Change management is more important than technology. Bring key users (warehouse staff, accountants) on board early, or the new system will be boycotted

Conclusion: How to Make the Right Decision

The question 'inventory management vs ERP' can't be answered with a simple checklist. It's a strategic decision about the future viability of your IT architecture.

Summary of Key Recommendations

- Stay with inventory management if your focus is purely on trading/logistics, your processes are lean, and you're doing well with 'Best-of-Breed' solutions (e.g., separate accounting)

- Switch to an ERP if you have complex value chains (manufacturing), international entanglements, or the need for a central data truth for all departments

- Examine hybrid models: Often a modern, API-based inventory management system combined with strong finance tools is more agile than a cumbersome ERP monster

- AI is mandatory: In 2025, don't invest in software that has no roadmap for AI integration

FAQ: Common Questions About WMS and ERP

Some modern cloud-based inventory management systems offer ERP modules (e.g., CRM, project management). However, these modules often fall short in depth compared to specialized ERPs. Carefully examine whether the 'light' versions meet your requirements before committing.

Inventory management often starts at a few hundred dollars per month (SaaS). A full ERP project for mid-sized businesses rarely starts under $50,000 (implementation + licenses in the first year) and can easily go into six figures. Factor in ongoing maintenance, training, and potential customization costs.

In 2025, the trend is massively toward cloud (SaaS). Advantages include: scalability, automatic updates (security!), access from anywhere. On-premise is almost only worthwhile for companies with extreme security requirements or poor internet connectivity in production, as noted by Comarch.

Inventory management tracks what products you have and where they are (the physical flow of goods). ERP does everything inventory management does PLUS financial accounting, HR management, customer relationships, and business analytics—essentially connecting every department in your company through one system.

Inventory management typically takes 2-6 months to implement fully. ERP implementation ranges from 6-18 months for mid-sized businesses, though complex enterprise deployments can take 2+ years. The hybrid Best-of-Breed approach can be implemented incrementally over time.

Don't risk a costly wrong purchase based on intuition. Our AI-powered analysis examines your specific data flows, processes, and growth trajectory to deliver personalized recommendations—not generic advice.

Start Free AI Analysis Now