The Paradigm Shift in Inventory Management

Inventory management is often viewed as a necessary evil—a pure back-office discipline that takes place somewhere between dusty shelves and complex Excel spreadsheets. For decades, the goal remained the same: reduce costs, save space, prevent shrinkage.

But we're writing the year 2026 (or standing right at its doorstep), and the rules of the game have fundamentally changed. In an era where customers expect real-time availability and AI-powered customer service is becoming the standard, it's no longer enough to simply manage inventory.

Those who still believe that warehousing is purely operational are losing real money. Modern inventory management is the foundation of your sales strategy. It's the fuel for AI agents that advise customers, and the key to turning a 'Unfortunately sold out' into 'Here's the perfect alternative.'

In this comprehensive guide, you'll learn how to transform your inventory management from a cost factor into a revenue driver, which KPIs really matter, and why Generative AI is finally closing the gap between warehouse and shopping cart.

What Is Inventory Management? The Basics & The Update

At its core, inventory management refers to the process of ordering, storing, using, and selling a company's inventory. It encompasses the management of raw materials, components, and finished products, as well as the storage and processing of these items. According to VersaCommerce, this traditional definition covers the fundamental logistics operations that every business needs.

But this classic definition falls short today. It describes a passive state: managing things that are there.

From Static to Active: The Modern Definition

To remain competitive in modern commerce, we need to expand the definition. It's no longer just about physical control—it's about data activation.

| Traditional Inventory Management | Modern Inventory Management (Activation) |

|---|---|

| Focus: Cost minimization & space optimization | Focus: Revenue maximization & customer experience |

| Data: Static (Excel, ERP reports) | Data: Real-time (API streams, AI-powered) |

| Reaction: Reorder when empty | Action: Predictive distribution & sales recommendations |

| Perspective: 'What do we have in stock?' | Perspective: 'What can we offer the customer right now?' |

Why This Distinction Matters for Your Bottom Line

Research from Databricks shows that retailers worldwide lose nearly $1 trillion in revenue because customers can't find products they're looking for (out-of-stock situations). Simultaneously, overstock massively ties up capital and causes storage costs. Modern management uses technology not just for counting, but to dynamically close this gap between supply and demand.

This is where AI product consultation becomes a game-changer. When your inventory data feeds intelligent systems that understand customer needs, you transform passive stock into active sales opportunities.

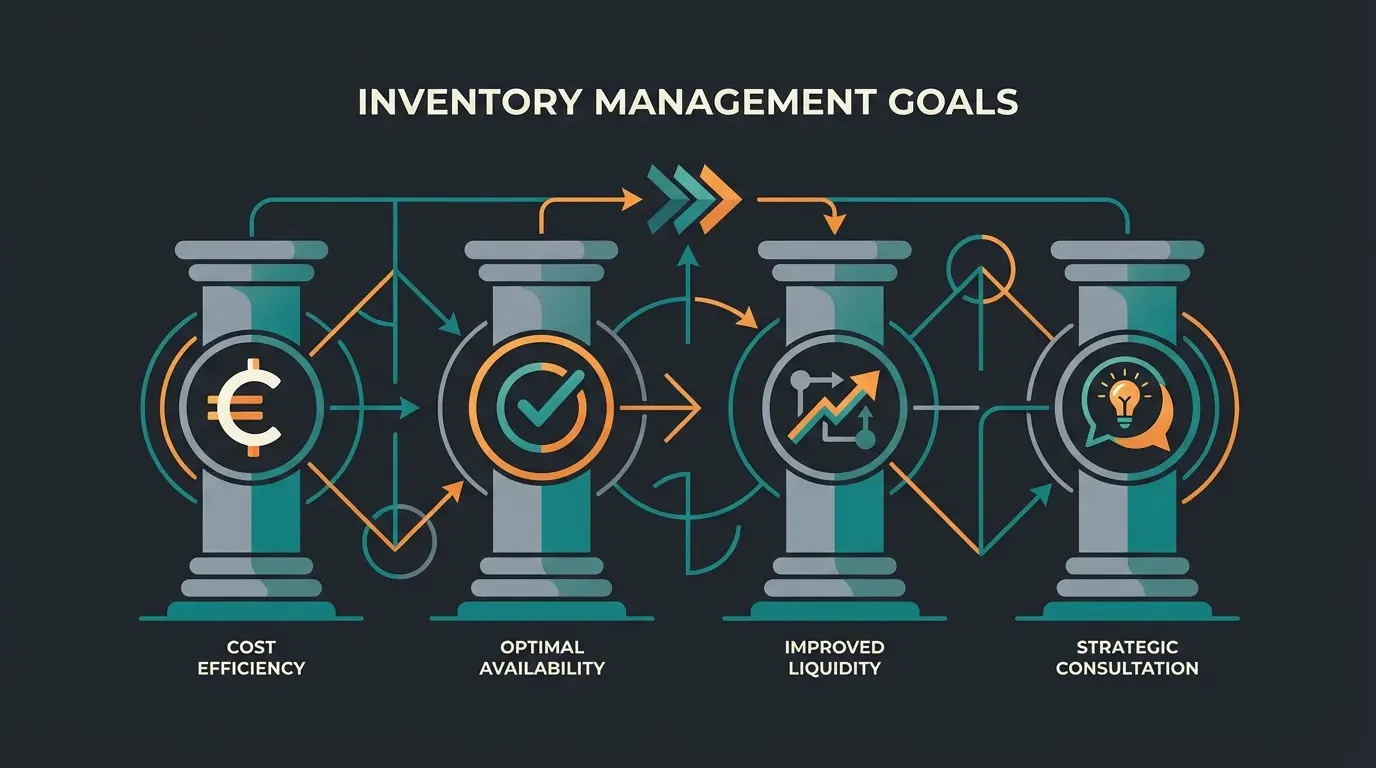

The 3 (+1) Main Goals: Cost, Availability & Consultation

Traditionally, inventory management operates within the 'magic triangle' of logistics. These goals often conflict with each other, and the art lies in finding the right balance.

1. Cost Minimization (Storage Costs)

Every item sitting on a shelf costs money. Rent, energy, insurance, personnel, and depreciation (obsolescence) all add up. According to Hublify, excessive inventory levels directly squeeze your margins.

- Goal: Store as little inventory as possible without compromising delivery capability

- Challenge: Balance lean operations with customer satisfaction

- Risk: Too aggressive reduction leads to stockouts and lost sales

2. High Availability (Delivery Readiness)

Nothing frustrates customers more than empty shelves or long delivery times. High availability secures sales and customer loyalty. As noted by Jungheinrich PROFISHOP, maintaining service levels to avoid stock-outs (shortages) is critical for sustained business success.

- Goal: Keep the 'service level' high to avoid stock-outs

- Challenge: Predicting demand accurately across seasons and trends

- Risk: Overstocking to ensure availability ties up capital

3. Low Capital Commitment (Liquidity)

Inventory in the warehouse is tied-up capital that cannot be used for investments, marketing, or innovation.

- Goal: Optimize cash flow by minimizing how long goods remain in company possession (high inventory turnover)

- Challenge: Balancing quick turnover with availability guarantees

- Risk: Cash flow constraints limiting growth opportunities

4. The New Goal: Consultation Accuracy

Here's your opportunity for differentiation. In an AI-driven world, your inventory data is the single source of truth for your sales bots. This is where solutions like AI Employee Kira demonstrate the power of inventory-aware consultation.

When your system says 'Stock: 0,' the conversation traditionally ends. But when your system reports 'Stock: 0, but Alternative X (Stock: 50) is 95% similar,' you save the sale.

Classic Methods for Optimizing Stock Levels

Before we dive into AI strategies, the homework needs to be done. These proven methods form the backbone of any optimal inventory management approach.

ABC Analysis: Prioritization Is Everything

Not every item is equally important. ABC analysis classifies inventory by its share of total revenue value. According to Tradelink and Veesion, this classification is fundamental to efficient resource allocation.

- A-Items: High value, low quantity (approx. 80% of value, 20% of quantity). Requires strict management and precise forecasting.

- B-Items: Medium value, medium quantity. Standard monitoring with periodic reviews.

- C-Items: Low value, high quantity (e.g., screws, C-parts). Often benefits from simplified management or bulk ordering.

XYZ Analysis: Consumption Predictability

This method examines fluctuations in consumption patterns:

- X-Articles: Constant consumption, high forecast accuracy (e.g., staple goods). Ideal for Just-in-Time approaches.

- Y-Articles: Fluctuating consumption (e.g., seasonal fashion). Requires safety stock buffers.

- Z-Articles: Completely irregular consumption. Difficult to plan, requires significant safety stock.

Just-in-Time (JIT) Strategy

The goal is to receive goods only when they're needed. This drastically reduces storage costs but increases risk during supply chain disruptions. Companies like AI Paul have shown how combining JIT with intelligent customer communication can mitigate these risks.

FIFO vs. LIFO: Choosing the Right Flow

- FIFO (First-In, First-Out): First stored goods are removed first. Standard for perishable goods or fashion (avoiding obsolescence).

- LIFO (Last-In, First-Out): Last stored goods are removed first. Less common, often used for bulk goods or tax valuation purposes.

Categorize items by their revenue contribution: A (80% value), B (15% value), C (5% value)

Evaluate demand predictability: X (stable), Y (variable), Z (irregular)

Combine classifications (AX, AY, AZ, BX, etc.) for nuanced strategies

AX items get JIT, CZ items get bulk ordering with higher safety stock

Essential Warehouse KPIs for 2026

Data is the gold of the 21st century, but only if you measure the right metrics. Beyond the classics, you should introduce new KPIs that measure inventory's impact on sales.

The Classic KPIs You Must Track

1. Inventory Turnover Rate

Indicates how often the average inventory completely sells or renews itself within a period. According to Xentral and Xorosoft, this is the most fundamental efficiency metric.

- Formula: Cost of Goods Sold / Average Inventory

- Interpretation: A high value indicates efficient warehousing and good sales. However, a value that's too high may indicate risk of stock-outs, as noted by Datawiz.

2. Average Inventory Duration

How long does a product sit in the warehouse on average?

- Formula: 360 Days / Turnover Rate

- Interpretation: The shorter, the better for liquidity and storage costs.

3. Reorder Point (Safety Stock Trigger)

The point at which a reorder must be triggered to avoid running empty before new goods arrive. WHK-Controlling provides detailed guidance on calculating this critical threshold.

- Formula: (Daily Consumption × Lead Time) + Safety Stock

- Application: Critical for A-items where stockouts directly impact revenue

The Next-Generation KPIs for AI-Era Commerce

4. Lost Sales Ratio

Measures the revenue lost due to stock-outs. Research from Efex and Inventory Planner confirms this as a critical metric.

- Formula: (Number of Lost Sales / Total Demand) × 100

- Why Important: Studies from RetailWire show that out-of-stock situations not only prevent current purchases but drive customers to competitors long-term.

5. Missed Opportunity Rate (The AI-Era KPI)

This is THE KPI for the AI age. It measures how often a customer asked for a product that was not available, but for which a suitable alternative was in stock that was not offered. The concept, adapted from healthcare where it measures missed treatment opportunities according to Population Health Learning Center and ResearchGate, translates directly to retail.

In commerce it means: Your warehouse was full of alternatives (B-grade items, different colors, successor models), but the sales process (human or bot) didn't activate these 'Inventory Assets.'

Annual losses from out-of-stock situations worldwide

Shoppers who switch to competitors after stockouts

Average capital tied up in excess inventory

Stock issues solvable with real-time data and AI

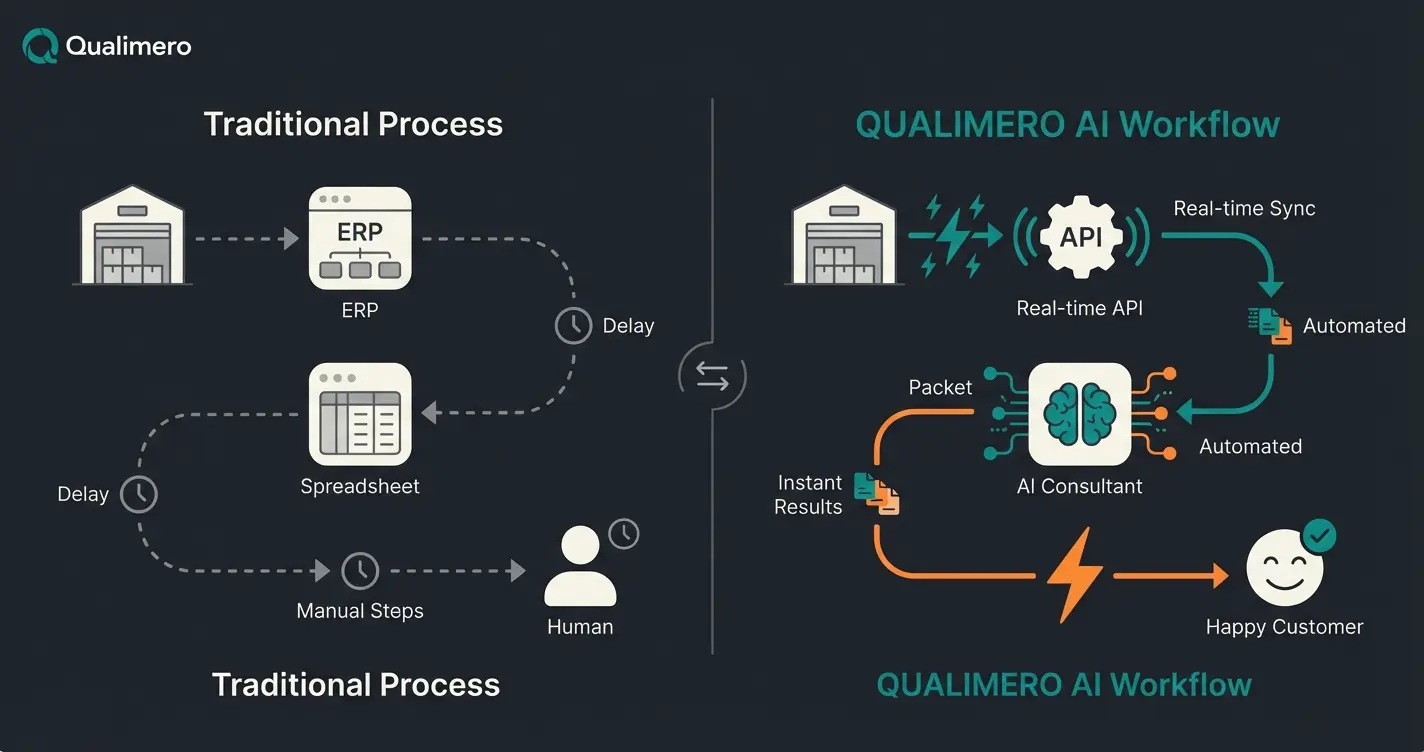

Why Traditional ERP Systems Often Fall Short

Many companies rely solely on their ERP (Enterprise Resource Planning) for their inventory management. This is correct for accounting and pure inventory tracking, but often a dead end for modern sales.

The Problem of Data Silos

In many companies, sales channels (online shop, retail store, marketplace) are technically separated. The ERP knows the total inventory, but synchronization often occurs with delays. According to Impact Analytics and Leafio, this fragmentation is one of the biggest challenges in modern retail.

Consequence: A customer buys the last item online while it's physically being sold in the store. Result: Overselling, cancellation, frustration. This is where AI lead generation tools can help by managing demand across channels intelligently.

Static Data vs. Dynamic Consultation

An ERP is a database for facts: 'Article 123: Stock 5.' But it doesn't understand context.

- It doesn't know that Article 123 (red sneakers) is a perfect alternative for Article 124 (dark red sneakers).

- It can't proactively inject 'slow movers' (shelf warmers) into sales conversations to clear the warehouse.

- It lacks the semantic understanding to match customer intent with available inventory.

This is where the gap emerges: The ERP manages inventory, but it doesn't actively help sell it. Companies like those using AI Employee Alex have bridged this gap successfully.

The Game Changer: AI in Inventory Management

Artificial Intelligence (AI) is transforming inventory management from reactive administration into a proactive strategy. We distinguish between two levels: Backend (Logistics) and Frontend (Customer Experience).

Backend: Predictive AI & Demand Forecasting

This is the area that most software vendors are already advertising today. AI analyzes historical sales data, seasonality, weather trends, and marketing campaigns to predict future demand. According to The Business Research Company, Eturns, and Medium, this represents a massive market opportunity.

- Advantage: More precise order quantities, fewer overstocks, fewer stock-outs

- Technology: Machine learning models recognize patterns that humans miss (e.g., correlation between local weather and specific product categories)

- Limitation: Still primarily backend-focused, doesn't directly impact customer conversations

Frontend: Generative AI & Inventory Activation

Here lies the true potential for 2026. Generative AI (like ChatGPT, but trained on your product data) functions as a bridge between inventory and customer. This is what KI Mitarbeiterin Flora demonstrates in practice.

The Intelligent Sales Consultant Scenario

Imagine a customer is searching in your chatbot for a specific outdoor shoe in size 43.

Scenario A (Classic): The system checks inventory. Result: 0. Response: 'Unfortunately sold out.' → Customer goes to Amazon.

Scenario B (AI-Powered): The AI uses RAG (Retrieval-Augmented Generation). It checks inventory (0) but understands the shoe's attributes (waterproof, hiking, price range). It scans inventory in real-time for alternatives.

AI Response: 'That model is unfortunately out of stock in size 43. But I see we have the MountainPro X in stock—it has the same sole and is currently 10% off. Would you like me to show it to you?'

Why This Technology Stack Works

- RAG Technology: Combines the AI's language capability with your real-time inventory data, as explained by EvidentlyAI and Tonic.ai. The AI doesn't 'hallucinate' stock levels—it accesses the database directly.

- Dead Stock Management: You can instruct the AI to specifically recommend products with high inventory levels (slow movers) when they match the customer's needs. According to PYMNTS, this actively clears inventory without discount battles.

- Omnichannel Integration: The AI can check: 'Online sold out, but your local store has two in stock. I can reserve one for you.' This capability is highlighted by Lumenalta as a key differentiator.

Success stories like AI Product Consultation and AI Chat show these principles in action across different industries.

The Difference: Static Bot vs. Inventory-Aware AI

| Feature | Classic FAQ Bot / Search Bar | AI Product Consultant (RAG) |

|---|---|---|

| Stock Check | Only checks exact SKU matches | Understands product attributes & context |

| Out-of-Stock Response | Dead end ('Not available') | Opportunity ('Here's an alternative') |

| Slow Movers | Gather dust in warehouse | Proactively recommended when relevant |

| Data Basis | Often delayed (batch updates) | Real-time API access |

| Customer Experience | 'I have to search' | 'I'm being advised' |

This transformation is what separates companies still struggling with inventory from those who have turned it into a competitive advantage. Solutions like AI Assistant Sophie demonstrate how this works in practice across service industries.

See how AI-powered inventory activation can turn stock-outs into cross-sells and slow movers into bestsellers. Our AI consultants integrate with your existing systems for real-time product recommendations.

Start Your Free TrialStep-by-Step Guide to Optimal Inventory Management

How do you get from paper chaos to AI-controlled warehousing? Here's a practical roadmap that organizations of all sizes can follow.

Step 1: Data Hygiene and Centralization

Before you can deploy AI, your data must be accurate. According to Impact Analytics and Leafio, data quality is the foundation of successful AI implementation.

- Consolidate all inventory data (warehouse, stores, dropshipping) into a 'Single Source of Truth'

- Clean up master data: Missing attributes (color, size, material) make it impossible for AI to find alternatives

- Establish data governance processes to maintain quality over time

Step 2: Calculate Safety Stock Levels

Use classic formulas to secure your foundation:

- Calculate the reorder point for your A-items using the formula: (Daily Consumption × Lead Time) + Safety Stock

- Analyze your suppliers' lead times to plan buffer times

- Consider seasonality and demand volatility in your calculations

Step 3: Implement Real-Time Tracking

Deploy barcode scanners or RFID to capture inventory movements immediately. According to ARMPOS, phantom inventory (stock that shows in the system but isn't physically there) is deadly for AI recommendations.

Step 4: The AI Connection (Inventory Activation)

Connect your inventory management to your sales channels. This is where AI employees for customer service become powerful tools for conversion optimization.

- Use tools or APIs that pass inventory data to your chatbot or search function

- Train the AI to treat 'out of stock' not as an error, but as a trigger for recommendations. Shopbox.ai provides excellent examples of this approach.

- Configure recommendation rules to prioritize slow-moving stock when it matches customer needs

Step 5: Monitor the New KPIs

Measure not just how full the warehouse is, but how well it sells:

- Track the Missed Opportunity Rate to identify consultation gaps

- Analyze how often AI recommendations lead to purchases (Conversion Rate of Alternatives)

- Monitor customer satisfaction scores for AI-assisted interactions

- Compare revenue per session with and without AI consultation

Unify all inventory sources into a single source of truth with complete product attributes

Establish reorder points for A-items based on consumption and lead times

Implement barcode/RFID for instant inventory movement capture

Connect inventory APIs to your chatbot for real-time consultation

Track Missed Opportunity Rate and alternative conversion metrics

Conclusion: The Warehouse as Competitive Advantage

Inventory management in 2026 is far more than counting boxes. It's the interface where efficiency meets customer experience.

While traditional companies are still trying to reduce their storage costs by 0.5%, market leaders are using their inventory data to revolutionize the shopping experience. They transform 'dead capital' into active sales arguments. Companies working with AI Employee Theresa exemplify this transformation.

The Key Takeaways for Implementation

- Integrate Sales & Logistics: Inventory data belongs in sales, not just accounting. Break down the silos between warehouse management and customer-facing systems.

- Use AI for Consultation: Let algorithms find alternatives instead of leaving customers alone with empty search results. This is where solutions like our AI employees for customer service excel.

- Measure Opportunity Costs: The most expensive inventory is what you could have sold but didn't offer. Track your Missed Opportunity Rate religiously.

- Think Beyond Stock Counts: Modern inventory management is about activation, not just administration.

Start today by not just managing your warehouse, but activating it. Because at the end of the day, the customer doesn't want perfect warehousing—they want the right product, immediately. Ready to see how this works in practice? Schedule a demo and discover the future of inventory-powered sales.

Bonus: Warehouse KPI Formula Cheat Sheet

Here are the essential formulas for optimizing your stock levels at a glance:

| KPI | Formula | Target |

|---|---|---|

| Inventory Turnover Rate | Cost of Goods Sold ÷ Average Inventory | High (but watch for stock-out risk) |

| Average Inventory | (Beginning Inventory + Ending Inventory) ÷ 2 | Baseline calculation |

| Reorder Point | (Daily Consumption × Lead Time) + Safety Stock | Prevent stockouts |

| Lost Sales Ratio | (Lost Sales ÷ Total Demand) × 100 | Minimize (<5%) |

| Days Sales of Inventory | (Average Inventory ÷ COGS) × 365 | Lower is better for cash flow |

Frequently Asked Questions

Inventory management focuses on optimizing stock levels, reorder points, and capital efficiency across all locations. Warehouse management deals with the physical operations within a single facility—receiving, storing, picking, and shipping. Modern businesses need both: inventory management for strategy and AI-powered consultation, warehouse management for operational efficiency.

While traditional AI focuses on predicting demand (backend), modern AI adds a frontend layer through intelligent product consultation. AI can check real-time stock, understand product attributes, recommend alternatives for out-of-stock items, proactively suggest slow-moving inventory, and check availability across omnichannel locations—all within customer conversations.

Beyond classics like Inventory Turnover Rate and Reorder Point, track 'next-gen' KPIs: Lost Sales Ratio measures revenue lost to stockouts, and Missed Opportunity Rate measures how often suitable alternatives existed but weren't offered. These metrics capture the sales impact of inventory decisions, not just operational efficiency.

Using RAG (Retrieval-Augmented Generation) technology, AI consultants access real-time inventory data while understanding product attributes and customer intent. When a requested item is unavailable, the AI immediately identifies similar products in stock and presents them as alternatives—converting potential bounces into cross-sell opportunities.

Inventory activation transforms static warehouse data into dynamic sales tools. Instead of just knowing 'what's in stock,' activation means making that data actionable for customer consultation, proactive slow-mover recommendations, and real-time availability checks across channels. It shifts inventory from a cost center to a revenue driver.

Join leading e-commerce brands using AI-powered inventory activation to transform stock management into sales strategy. Our intelligent consultants integrate seamlessly with your existing systems.

Get Started Free