Why Excel and Pen Are Costing You Real Money

Have you ever stood in front of a closed store with a sign reading "Closed for inventory"? Or have you spent countless weekends entering dusty stock counts into endless Excel spreadsheets, only to discover at the end that the numbers don't add up anyway?

The annual stocktake remains a necessary evil for many mid-sized companies—a bureaucratic ordeal driven by fear of tax authorities and the strict requirements of commercial law. Yet while most businesses view inventory as merely a compliance obligation, a quiet revolution is taking place behind the scenes.

In 2025, inventory software is no longer just a digital clipboard. It's the fundamental data backbone for modern sales strategies. In an era where customers expect real-time answers and Artificial Intelligence (AI) is redefining retail, your stock levels become your most valuable currency.

This article shows you not only how to digitize your inventory in a legally compliant and efficient manner. We go one crucial step further: we illuminate how you can use your stock data to transform from passive administrator to active seller—supported by cutting-edge AI technology.

The Current State: Hidden Costs of Manual Processes

Many businesses still rely on spreadsheets for their inventory management. At first glance, this appears cost-effective and flexible. But the hidden costs of this "free solution" are immense.

The Statistics of Failure

Current research paints a clear picture of manual process inefficiency. According to SystemSync, automated systems can reduce up to 90% of errors that occur with manual entries, and companies can save up to 75% of time previously spent on manual routine tasks when they embrace automation.

Automated systems eliminate up to 90% of manual entry errors

Automation cuts time spent on routine inventory tasks by three-quarters

Manual warehouse processes create significantly higher operational overhead

Research from Pragmatic Apps confirms that manual warehouse processes cause an average of 20-30% more overhead compared to automated solutions.

The Problem of Siloed Data

An inventory program based on Excel is static. As soon as the list is printed or saved, it's outdated. There's no real-time synchronization. When an item is sold, the Excel spreadsheet knows nothing about it until someone manually updates it.

This leads to two classic scenarios:

- Out-of-Stock: A customer wants to buy, but the item physically isn't there, even though the list says "Stock: 5."

- Overstock: Out of fear of shortages, too much is ordered, tying up capital unnecessarily.

What Is Modern Inventory Software? Definitions & Basics

When we talk about inventory software today, we mean far more than a digital counting tool.

Definition of Digital Inventory Solutions

A modern digital inventory solution is a cloud-based system that synchronizes physical stock with digital databases in real-time. It replaces paper chaos with digital capture devices (scanners, smartphones) and serves as the "Single Source of Truth" for the entire organization.

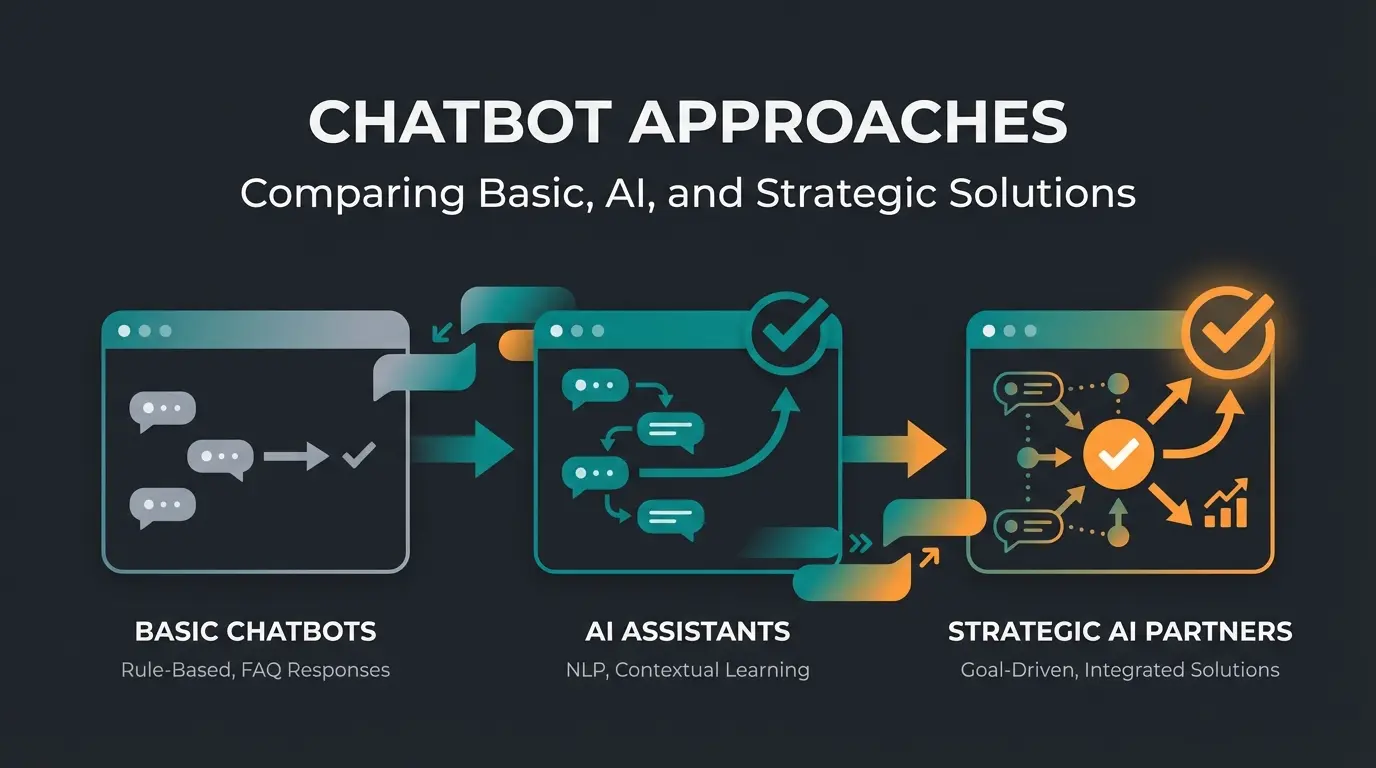

The Difference: Administration vs. Intelligence

The market currently divides into two camps:

- Classic Administration Tools: These focus purely on meeting legal requirements. They count, document, and archive.

- Smart Inventory Systems: These systems understand stock data as fuel for other business areas—especially sales and customer service.

Companies that embrace AI product consultation understand that inventory data isn't just for compliance—it's the foundation for intelligent customer interactions.

Why Cloud Is No Longer Optional

Previously, software was often "on-premise," meaning installed on a company computer. Today, cloud is standard. Here's why:

- Access from anywhere: The warehouse worker scans in the basement, procurement checks from home office, sales views data at customer locations.

- Real-time data: Every change is immediately visible to everyone.

- Interfaces (API): Only cloud systems can seamlessly connect with modern AI tools, online shops (Shopify, WooCommerce), and ERP systems.

Core Features Comparison: What Matters in 2025

Before we dive into revolutionary AI features, the foundation must be solid. A robust inventory app must meet these "table stakes" (basic requirements) in 2025:

The Must-Have Checklist

| Feature | Why It's Essential |

|---|---|

| Mobile Data Capture | Inventory with scanner or smartphone must happen directly at the shelf. No one should have to type lists anymore. |

| Barcode & QR Code Scanning | Fast item identification. Modern apps recognize damaged codes or scan multiple codes simultaneously (multi-scan). |

| Real-Time Synchronization | "Batch processing" (data transfer at end of day) is dead. When an item is scanned, stock must update instantly in the system. |

| API Interfaces | The most important feature for the future. Software must "talk" to your CRM, shop, and AI assistants. |

| Offline Capability | Even in the deepest warehouse without WiFi, the app must function and sync data once connectivity returns. |

| User Rights & Logging | Who changed what and when? Critical for audit compliance and resolving inventory discrepancies (theft/shrinkage). |

Import & Export: The Death of Island Solutions

Inventory software that cannot import data (e.g., item master data from ERP) or export data (e.g., stock valuation for accountants) is useless. Look for seamless CSV, Excel, and especially REST API connections.

The Game Changer: AI in Stock Management

This is where the wheat separates from the chaff. While conventional providers still debate how to scan barcodes faster, Artificial Intelligence (AI) is revolutionizing the purpose of stock data.

From Counting to Consulting: Your Competitive Edge

The biggest mistake companies make is viewing inventory as a purely internal administrative task. The new approach: Your stock data is the brain of your sales operation.

Consider this scenario: A customer visits your online store or chats with your AI support bot. They ask: "I urgently need 50 red safety helmets for a construction site."

- Without modern software: The bot (or employee) must check the system, perhaps finds outdated data, must call the warehouse. The customer waits—and buys elsewhere.

- With AI-powered inventory software: The AI accesses real-time stock in milliseconds. It responds: "We currently have 42 in stock that can arrive tomorrow. The remaining 8 can ship from Branch B, arriving the day after. Shall I place the order?"

This is precisely how AI employee Kira operates—combining real-time data access with intelligent customer consultation to drive conversions.

Physical inventory sits in warehouse location

Mobile device captures barcode/QR code

Real-time synchronization to central system

Sales AI queries current stock levels

Informed recommendation leads to sale

Predictive Analytics: The Crystal Ball for Your Warehouse

AI can recognize patterns no human can see. By analyzing historical sales data, seasonal trends, and even weather data, AI can predict demand before it happens.

According to SuperAGI research, AI-powered forecasts can reduce prediction errors by 20-50%. The result: You avoid "dead stock" (shelf warmers) while simultaneously preventing out-of-stock situations for bestsellers. McKinsey reports that AI-driven inventory management can reduce stockouts by up to 65%.

Solutions like AI product consultation demonstrate how predictive capabilities transform reactive businesses into proactive market leaders.

Visual Recognition: The Eye of AI

Modern inventory apps utilize computer vision. Instead of "beeping" every barcode individually, employees hold their smartphone toward a shelf. The AI recognizes all items in the image, counts them, and compares against target stock. This massively accelerates inventory and reduces human counting errors.

Stop treating stock data as a compliance burden. Discover how AI-powered inventory management drives real-time product consultation and increases conversions.

Start Your Free TrialLegal Compliance 2025: E-Invoicing and Regulations

In business, you can't escape compliance requirements. The year 2025 brings massive changes that must influence your software choice.

The E-Invoice Mandate Starting January 1, 2025

Since January 2025, e-invoicing in B2B transactions has become mandatory in many jurisdictions. According to N-Komm, Ecovis, and EU-Rechnung:

- What does this mean? A simple PDF no longer qualifies as an electronic invoice under new standards (EN 16931). Structured formats like XRechnung or ZUGFeRD are required.

- Impact on inventory: When purchasing goods, your inventory or merchandise management software must directly process structured invoice data (XML) and automatically increase stock levels. Manually typing invoices is not only inefficient but barely practical with new formats.

Compliance Standards: No Compromises

Proper record-keeping principles were updated in 2024 and 2025. Your inventory software must guarantee:

- Immutability: Once finalized bookings cannot be deleted without trace.

- Traceability: Every stock change requires a log (Who, When, What).

- Timely Recording: Digital capture enables deadline compliance far better than paper lists typed days later.

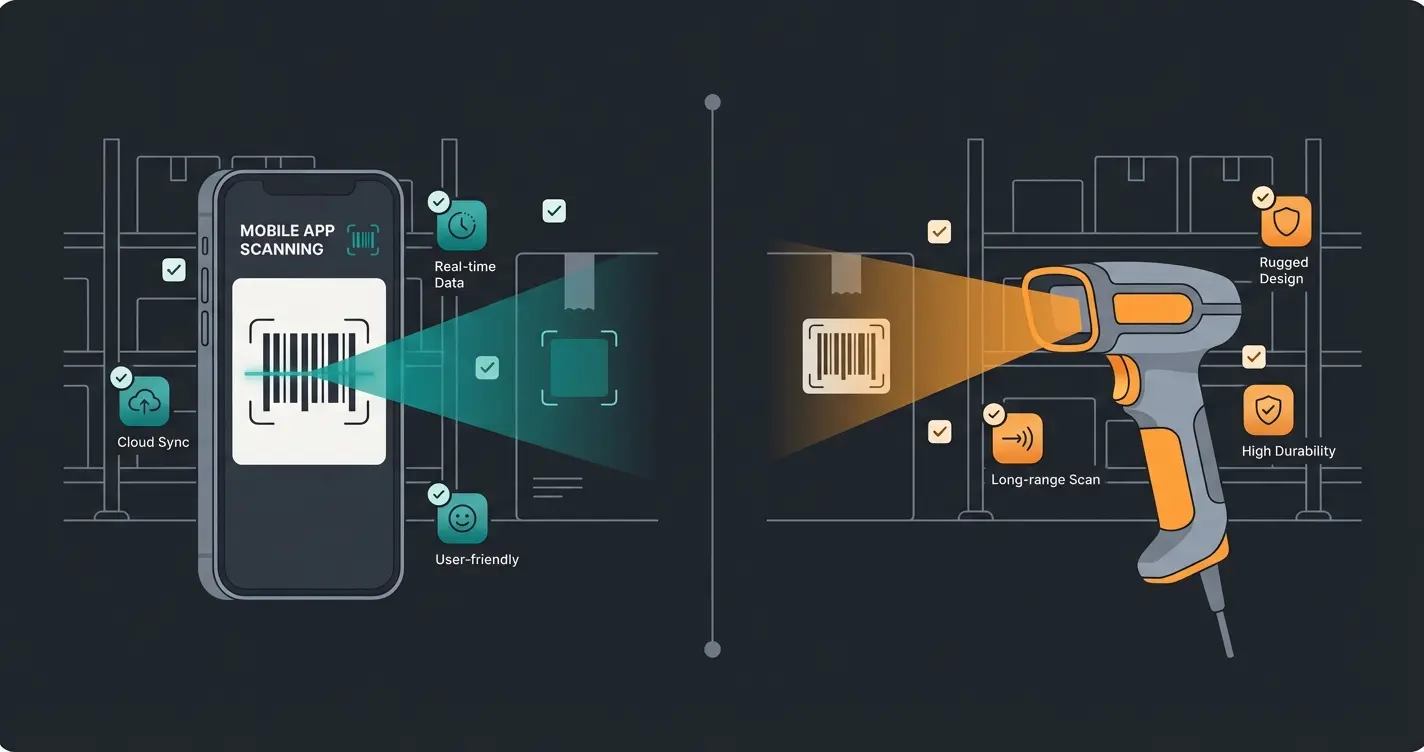

Hardware Check: Scanner vs. Smartphone App

The days when you had to buy bulky industrial scanners for €2,000 each are over.

The Trend: BYOD (Bring Your Own Device)

Modern inventory apps transform any standard smartphone (iOS & Android) into a high-performance scanner.

Advantages:

- Cost: No expensive specialized hardware required.

- Training: Every employee knows how to use a smartphone.

- Flexibility: During peak loads (e.g., annual inventory), temporary workers can simply use their own phones.

Organizations implementing product consultation AI solutions find that smartphone-based inventory creates seamless data flow between stock management and customer-facing AI systems.

When Does an Industrial Scanner Still Make Sense?

For high-performance warehouses where forklift drivers need to scan from 5 meters away, or where devices regularly fall on concrete floors, rugged MDE devices (Mobile Data Entry) still have their place. Good inventory software supports both: the app on smartphones for retail locations and rugged scanners for central warehouses.

| Factor | Excel/Manual | Standard Inventory App | AI-Powered Solution |

|---|---|---|---|

| Initial Cost | Free | $50-200/month | $200-500/month |

| Speed | Hours per inventory | Minutes per section | Real-time continuous |

| Error Rate | 5-15% | 1-3% | <0.5% |

| Sales Integration | None | Basic export | Full API + AI consultation |

| Predictive Capability | None | Basic reporting | Demand forecasting |

| Compliance Ready | No | Partial | Full audit trail |

Step-by-Step Implementation and Best Practices

Switching from Excel or paper to a digital solution often seems daunting. But with the right strategy, it's achievable in just a few days.

Phase 1: Data Cleansing (The Most Important Step)

Before importing data into a new system, it must be clean:

- Remove duplicates.

- Standardize item numbers.

- Add missing EAN/GTIN codes (essential for scanners!).

Phase 2: The Test Inventory

Don't start directly with annual inventory. Conduct a "perpetual inventory" in a small product category:

- Test the inventory app under real conditions (check WiFi coverage in warehouse!).

- Measure time savings compared to the old method.

Companies like those using AI sales consulting started with pilot programs before full rollout—a proven path to success.

Phase 3: Integration of AI Components

Once stock data flows, connect it to your sales channels:

- Link the API with your webshop to prevent "overselling."

- Use the data for your AI sales bot to proactively offer alternatives when an item runs low.

- Connect to AI employee Theresa type solutions for automated customer service integration.

Legacy Tools vs. AI-Driven Solutions Comparison

Understanding the fundamental differences between traditional inventory approaches and modern AI-powered solutions helps clarify the transformation opportunity:

| Capability | Legacy Approach | AI-Driven Solution |

|---|---|---|

| Data Entry | Manual input, batch processing | Automated capture, real-time sync |

| Stock Visibility | Periodic snapshots | Continuous real-time view |

| Error Handling | Post-hoc corrections | Predictive prevention |

| Sales Integration | Siloed data, manual lookup | Direct AI assistant access |

| Customer Experience | "Let me check the warehouse" | Instant availability confirmation |

| Demand Planning | Historical guesswork | Predictive analytics |

| Compliance | Manual documentation | Automated audit trails |

Organizations implementing AI recruiter solutions for hiring often find that the same data-first principles apply to inventory management—structured, accessible data enables intelligent automation.

Future Outlook: Inventory as Competitive Advantage

The question in 2025 is no longer: "Which program helps me count my items?" The question is: "How do I leverage my knowledge of stock to sell more and advise customers better?"

While traditional inventory software and Excel spreadsheets merely manage (and often falsify) the status quo, AI-powered solutions open the door to a new era of commerce:

- They drastically reduce manual effort and error rates.

- They almost automatically meet complex compliance requirements.

- Most importantly: They transform your warehouse from a cost center into an active sales assistant.

Forward-thinking businesses are already connecting inventory systems to WhatsApp automation for instant customer communication about product availability.

FAQ: Common Questions About Inventory Software

For very small hobby shops, freeware or Excel may suffice. However, as soon as you need to work in compliance with regulations, have employees, or require interfaces to online shops, free tools immediately hit their limits. The costs of errors and time loss quickly exceed the license fees of professional software. Businesses handling B2B transactions must process structured invoice formats—capabilities free tools simply don't offer.

Yes. Modern smartphone cameras and intelligent scanning algorithms in inventory apps are now powerful enough to replace dedicated barcode scanners in 90% of cases. The key is choosing software with robust offline capability and multi-scan features. For high-volume warehouses or harsh environments, dedicated industrial scanners may still be preferable.

AI assists on two levels: Operationally, through image recognition (visual computing), shelves can be captured faster and counted automatically. Strategically, predictive analytics forecasts when goods will run out before it happens, enabling automated reordering and better customer consultation through real-time availability information.

The goods receiving process becomes more digital. Paper invoices are disappearing. Your software must be able to directly process digital invoice data (XML/ZUGFeRD) to automatically book stock without anyone having to manually enter delivery notes. This requirement makes API connectivity essential rather than optional.

With proper planning, most businesses achieve full implementation within 2-4 weeks. Phase 1 (data cleansing) typically takes 3-5 days, Phase 2 (pilot testing) another week, and Phase 3 (full rollout with AI integration) 1-2 weeks. The key is starting with clean data and a limited product category before scaling.

Ready to Transform Your Inventory Strategy?

Stop wasting time hunting for errors in Excel spreadsheets. Stop losing sales because your stock data lives in silos. Stop treating inventory as a burden when it could be your greatest competitive advantage.

The technology exists today to transform every barcode scan into actionable sales intelligence. Your competitors who embrace AI-powered inventory management aren't just counting faster—they're selling smarter.

Join forward-thinking businesses using AI to transform inventory data into real-time customer consultation. See how your stock can actively drive sales instead of just sitting on shelves.

Get Started Free