The End of 'Dumb' Inventory: A New Era Begins

Picture this scenario: A B2B customer urgently orders a replacement part for a production machine. Your warehouse worker scans the item, the system gives the green light—inventory matches, storage location is correct. The package ships out. Two days later, an angry phone call comes in: The part doesn't technically fit the customer's machine model year.

The consequences? An expensive return, frustrated customer, and unnecessary logistics costs. But was it a warehouse error? Technically, no. Your warehouse management software did exactly what it was supposed to: it told you where the item was stored. But it didn't know what the item actually was or the context in which it was needed.

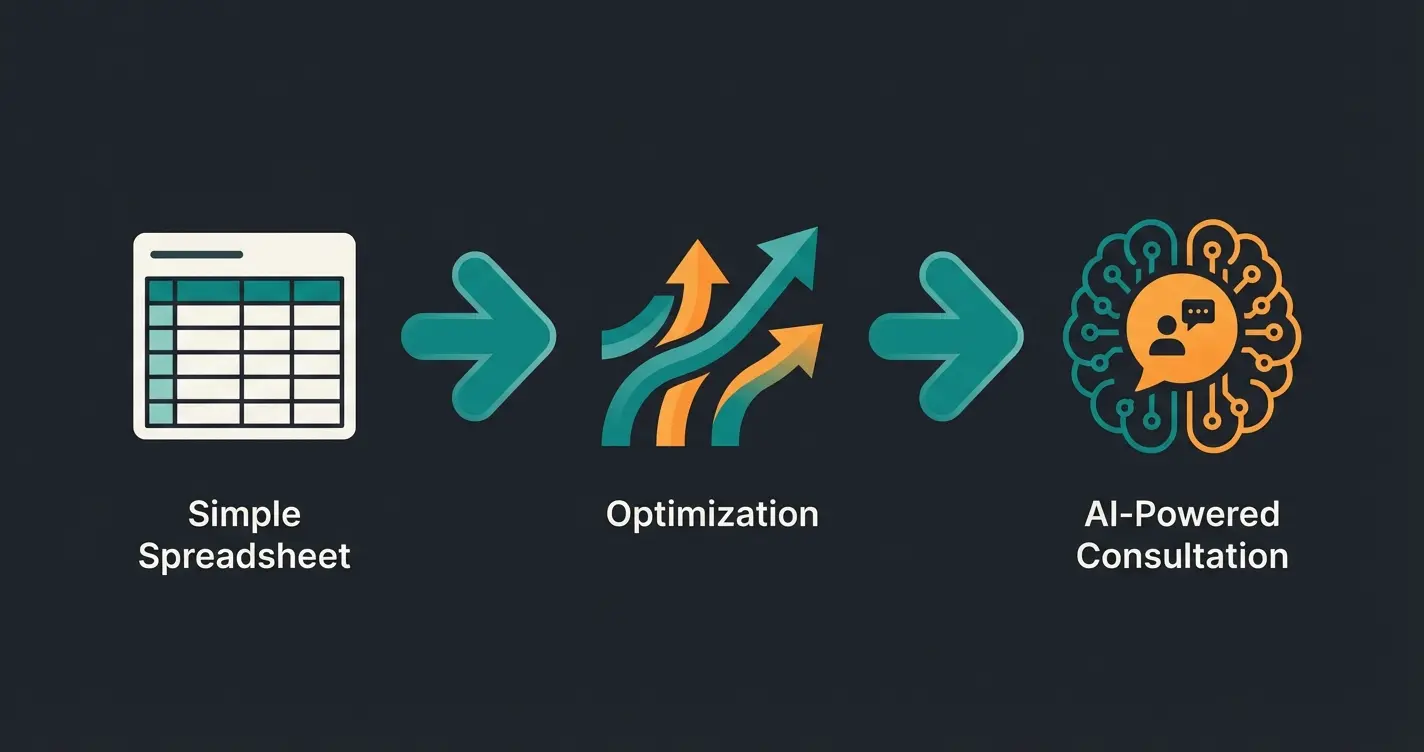

This is precisely where we stand at a turning point in 2026. While traditional WMS software (Warehouse Management Systems) functioned for decades as passive databases—essentially glorified Excel spreadsheets—we're now entering the era of intelligent assistants. According to IONOS, cloud solutions and AI integrations have become the standard for competitive warehouse operations, no longer relegated to niche applications.

In this comprehensive guide, we'll analyze not only the best tools for warehouse management software on the market but also demonstrate why the shift from a managing system to a consulting system ('Consultative Intelligence') will become your greatest competitive advantage in logistics. We're bridging the gap between simple inventory management and true, AI-driven warehouse logistics. For businesses looking to enhance customer interactions alongside their logistics, AI-powered customer service solutions offer complementary capabilities that extend this intelligent approach to the entire customer journey.

What Is Warehouse Management Software Today?

To make the right decision, we first need to sharpen our terminology. Terms like warehouse software, WMS software, and ERP are often thrown around interchangeably, but understanding the distinctions is crucial for your investment planning.

Definition: WMS vs. LVS vs. ERP—Understanding the Differences

The differentiation is essential for your investment planning:

- Inventory Management Software (LVS): This is the umbrella term. LVS focuses on quantity and location-based inventory management. It answers the questions: What do I have? Where is it located?

- Warehouse Management System (WMS): A WMS software system goes deeper. It controls and optimizes internal material flows. It's the 'brain' of the warehouse, optimizing walking routes, specifying picking strategies (like wave-picking), and controlling technology (e.g., conveyor belts). As noted by Systemhaus, specialized WMS functions are essential for e-commerce and B2B logistics.

- ERP (Enterprise Resource Planning): The ERP is the commercial headquarters (finance, purchasing, sales). It often includes a simple warehouse module. However, for complex logistics, the 'warehouse module' of a standard ERP often isn't sufficient, which is why modern WMS systems dock onto the ERP as specialized satellites.

The Evolution: From Bookkeeper to Consultant

The market has changed dramatically. As recently as 2020, the focus was on digitizing paper lists. In 2026, we expect systems that think along with us:

- Past (The Bookkeeper): 'You have 50 units of Item A at Location B.'

- Present (The Optimizer): 'Pick Item A from Location B because that's the shortest route.'

- Future 2026 (The Consultant): 'Warning: You've picked Item A for Customer X. However, this customer has Machine Y. Item A frequently causes failures there. Should I suggest Item C instead?'

This transformation is driven by AI technologies that we'll examine in detail later (see the 'Consultation Gap' section). The shift represents a fundamental change in how businesses approach inventory—from reactive management to proactive intelligence.

Key Features Comparison: Standard vs. Intelligent WMS

When you compare warehouse management software today, you're bombarded with feature lists. But which functions are 'nice-to-have' and which are 'must-have' in 2026? We distinguish here between basic functions (Legacy) and intelligent functions of the next generation.

| Function Area | Standard Function (Legacy WMS) | Intelligent Function (AI-WMS 2026) |

|---|---|---|

| Inventory Management | Real-time inventory display, inventory lists | Predictive Stocking: AI predicts stock-outs before they happen |

| Order Picking | Digital pick lists, MDE support (barcodes) | Dynamic Route Calculation: Real-time route adjustment when another picker blocks the aisle |

| Goods Receipt | Manual scanning and booking | Visual Recognition: AI identifies items via camera/image recognition and checks for damage without manual scanning |

| Storage Location | Fixed or chaotic warehousing by rules | Smart Slotting: System learns seasonal trends and suggests: 'Christmas is coming, store Item X closer to shipping' |

| Returns | Recording return reasons | Return Prevention: Analysis of why items come back (e.g., 'Fit runs small') and warning in the shop before purchase |

| Interfaces | Rigid connection to shop/ERP | Autonomous Agents: Self-healing interfaces that correct data errors |

According to research from Circly and SC Logistics, predictive analytics in warehouse management can reduce stock-outs by up to 30% while simultaneously decreasing excess inventory. This represents a fundamental shift from reactive to proactive inventory management.

Why Barcodes Alone No Longer Suffice

A warehouse management system that only scans barcodes prevents you from finding nothing, but it doesn't prevent you from doing the wrong thing regarding customer needs. Modern systems like JTL-Wawi or xentral increasingly integrate AI features to not just store data but make it actionable. According to Go-Ecommerce, JTL is increasingly integrating AI features for product descriptions and data maintenance through partners and connectors.

The real differentiation comes when your warehouse software doesn't just answer 'Where is it?' but also 'Is this the right item for this customer's specific situation?' This contextual awareness is what separates modern intelligent systems from traditional inventory trackers.

Including shipping, returns, handling, and value loss

German online retail average, up to 50% in fashion

When switching to intelligent WMS software

Achievable with modern AI-enhanced systems

Market Overview: Which Solution Fits Your Business?

The German market for warehouse management software is fragmented. Based on our analysis of top search results and current market data, solutions can be divided into three clear clusters.

A. For E-Commerce Startups & Small Retailers

Focus here is on simple connection to shops (Shopify, Amazon) and quick startup. Budget constraints and agility requirements drive these choices.

Top Candidate: JTL-Wawi — This solution is extremely widespread in German e-commerce. The basic version is free, making entry easy. JTL increasingly integrates AI features (e.g., for product descriptions and data maintenance) through partners and connectors. Ideal for retailers with high shipping volume but limited budget.

Top Candidate: Pickware — According to Pickware, this solution integrates seamlessly into Shopware and Shopify. It's not an external system but lives directly in the shop backend. Ideal for pure Shopware/Shopify users who don't want separate IT infrastructure.

Additional Options: SevDesk offers simpler inventory management, though with less deep WMS functionality according to IONOS.

B. For Mid-Market & Growth Companies

Here, process automation and scalability become more important than price alone.

Top Candidate: xentral — Xentral positions itself strongly as a 'Next Gen ERP' with a focus on automation. According to Xentral, the new reporting module with AI Copilot allows querying warehouse data in natural language ('Which items have the worst turnover?'). Ideal for D2C brands and retailers growing quickly who need to map complex processes (fulfillment, multi-warehouse).

Top Candidate: weclapp — As noted by Weclapp, this cloud-based ERP has a strong focus on usability and mobile apps. The warehouse app is deeply integrated and allows complex strategies like serial number tracking and batch management. Ideal for teams seeking an all-in-one solution (CRM + ERP + WMS) who work mobile.

C. For Enterprise & Complex Logistics

When hardware (conveyor technology, robots) needs to be controlled, enterprise-grade solutions become necessary.

Top Candidate: Mecalux Easy WMS — Mecalux comes from rack construction. Their software controls physical automation. According to Mecalux, they already offer generative AI features for data analysis in the warehouse.

Top Candidate: SAP EWM — The market standard for corporations. Extremely powerful but implementation-intensive, as detailed by ATA Solutions. This remains the go-to choice for organizations with complex global logistics requirements and existing SAP infrastructure.

Discover how AI-powered solutions can bridge the gap between simple inventory management and intelligent product consultation. Join forward-thinking businesses already leveraging consultative intelligence.

Get Started FreeThe Consultation Gap: Why Simple Bots Fall Short

This is the most important section for your future strategy. Most providers and comparison portals talk about efficiency (faster picking). That's important, but it doesn't solve the problem of the quality of the logistics decision.

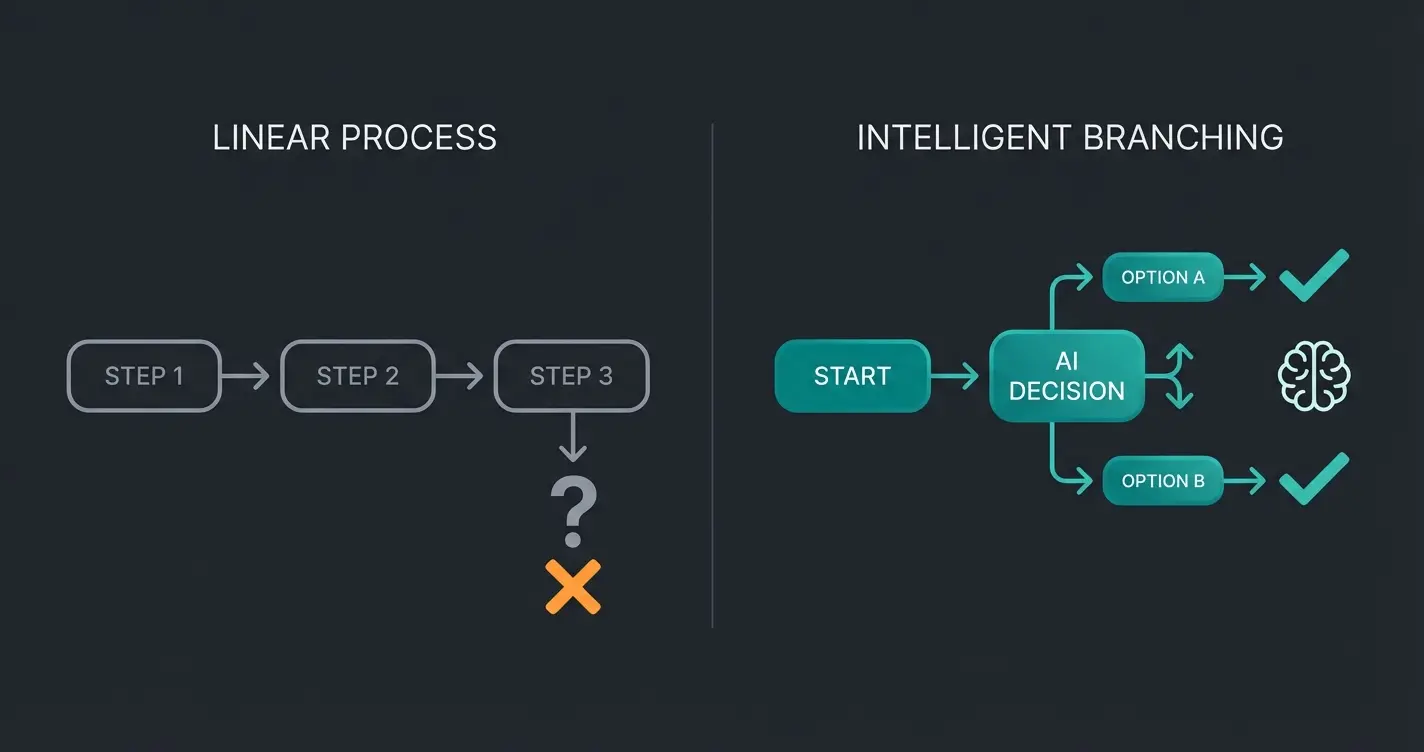

The Problem: The Silent Servant

A conventional warehouse management system is a silent servant. It executes commands without understanding context:

- Command: 'Send 10x Filter X to Customer Y.'

- Execution: The WMS guides to the storage location, the item is scanned, shipped.

- Result: Customer Y is dissatisfied because Filter X doesn't fit their new system.

This scenario plays out thousands of times daily across warehouses worldwide. The system technically performed flawlessly—inventory was accurate, the pick was correct, shipping was on time. Yet the outcome was a costly failure because the software lacked product intelligence.

The Solution: Consultative Intelligence (AI as Advisor)

The next generation of warehouse software (2026+) uses AI to understand context. It connects inventory data with product data and customer history. This approach mirrors what businesses can achieve with AI product consultation on the customer-facing side—extending intelligent guidance throughout the entire order lifecycle.

This is the Consultation Gap. Normal software finds inventory. Intelligent software prevents errors through product knowledge. According to studies cited by Logistik Express, the costs for a single picking error (shipping, return, handling, value loss) exceed €17, sometimes significantly higher for complex goods.

With an average return rate of 11% in German online retail (and up to 50% in fashion) according to Bitkom, there's a massive lever for profit maximization here that pure 'management tools' leave untouched. The financial impact of preventing even a fraction of these returns through intelligent consultation far outweighs the software investment.

Order enters the system with product selection and shipping details

Traditional system confirms stock availability and guides to shelf location

Intelligent system cross-references customer history, product compatibility, and common issues

AI warns of potential mismatches: 'This part typically doesn't fit machines from before 2020'

Staff can verify with customer or suggest alternatives before shipping

Correct item reaches satisfied customer, return prevented

Cloud vs. On-Premise: What's More Future-Proof?

One of the most common questions when purchasing is the deployment method. Analysis of search results shows that cloud solutions (SaaS) dominate the market, though on-premise (local installation) still exists in certain niches.

Why Cloud Wins in 2026

The main reason isn't just flexibility—it's AI capability. To use functions like Predictive Analytics or Image Recognition, the software needs computing power and training data that local servers rarely provide.

Cloud (SaaS) Advantages:

- Always current with automatic updates

- Scalable resources on demand

- AI features often included (see xentral, weclapp)

- No own server maintenance required

- Better integration with modern webshops and marketplaces

Cloud (SaaS) Considerations:

- Ongoing subscription costs

- Dependency on internet connectivity

- Data stored externally (though typically with robust security)

On-Premise Considerations: While offering one-time license costs (seemingly cheaper, but watch maintenance) and full data control in-house, on-premise solutions age quickly, struggle with modern webshop/marketplace integration, and make AI integration nearly impossible. According to OMR, even older JTL installations often still run locally, but the trend clearly moves toward cloud hosting.

Bottom Line: Anyone wanting 'Warehouse Management 2.0' can hardly avoid the cloud. AI models like the Copilot from Xentral or the Easy AI from Mecalux require cloud connectivity to function effectively.

Checklist: Finding the Best WMS Software

Before deciding on a warehouse management system, use this checklist. We've deliberately included points that go beyond the standard and secure your future viability.

Phase 1: Basics (Must Be Met)

- Interface Compatibility: Do ready-made connectors exist for my shop (Shopify, Shopware) and marketplaces (Amazon, eBay)?

- Hardware Independence: Does the picking app run on affordable Android devices, or do I need expensive specialized scanners? (Weclapp and Pickware, for example, use iOS/Android)

- Process Coverage: Does the system handle my required strategies (e.g., batch management, expiration dates, serial numbers)?

Phase 2: Scalability & Automation

- Shipping Integration: Can shipping labels (DHL, UPS) be printed directly in the process (without CSV export)?

- Automatic Routing: Can the system automatically split orders when items are in different warehouses?

- Multi-Channel Support: Does the software handle orders from multiple sales channels seamlessly?

Phase 3: Future-Proofing (The AI Test)

- Consultative Features: Does the manufacturer offer a roadmap for AI? (Are there approaches for anomaly detection or smart inventory planning?)

- Data Accessibility: Can I easily access my data for analysis (e.g., via open APIs or integrated BI tools like at Xentral)?

- User Guidance: Is the interface intuitive enough that temporary workers can be trained in 15 minutes? (Visual aids instead of text walls)

- Product Intelligence: Does the software understand my product logic, not just locations?

This last point is crucial and often overlooked. Traditional evaluation criteria focus on operational efficiency, but the real differentiator in 2026 is whether your WMS can prevent errors through product understanding—similar to how AI lead generation solutions qualify prospects through intelligent analysis rather than simple data collection.

Costs & ROI: What Does It Actually Cost?

The question 'What does warehouse management software cost?' is omnipresent in search results. The answer has changed through SaaS models.

Pricing Models 2025/2026

Freemium / Entry Level: JTL-Wawi (free in the basic version), additional modules cost extra. Costs range from €0 - €100/month. Ideal for testing and small operations.

SaaS / Cloud ERP (Mid-Market): Examples include xentral and weclapp with pricing per user or order volume. According to OMR, typical costs range from €150 - €1,000/month depending on company size and user count.

Enterprise / On-Premise: License purchase + maintenance contract + implementation model. Often five-figure initial costs plus ongoing maintenance. Suitable only for large operations with specific requirements.

The 'Cost of Error' Calculator: Why €500/Month Pays Off

Calculate your error costs against the software investment:

| Factor | Calculation | Monthly Impact |

|---|---|---|

| Monthly Shipments | 500 packages | - |

| Manual Error Rate | 2% (10 packages) | 10 errors |

| Cost per Error | ~€17.00 | €170 direct loss |

| Image & Trust Loss | Difficult to quantify | Significant long-term impact |

| Total Monthly Loss | Direct + Indirect | €170+ per month |

A good WMS system pushes error rates often below 0.1%. Error prevention alone often finances the software for smaller retailers. Add time savings during inventory and picking, and the ROI becomes clear within months, not years.

When evaluating costs, also consider the opportunity cost of staff time spent handling returns and customer complaints. Businesses that have implemented AI employees alongside their WMS report significant reductions in support inquiries related to order and shipping issues.

Frequently Asked Questions About Warehouse Management

Yes, there are open-source solutions and free basic versions of commercial providers like JTL-Wawi. These are excellent for getting started. However, note that 'free' often means investing more time in setup and maintenance. For growing companies, support is often more important than license cost savings. The true cost of 'free' software often emerges in implementation time and limited functionality.

ERP (Enterprise Resource Planning) is the generalist for the entire company (invoicing, HR, purchasing). WMS (Warehouse Management System) is the specialist for the warehouse. It controls walking routes, scanners, and storage locations. Good ERP systems like weclapp or xentral have strong WMS integrated, so small to medium businesses often don't need a separate WMS. The key is ensuring your chosen solution handles your specific complexity level.

Beyond marketing hype, AI helps concretely in three areas in 2026: First, Forecasting—better prediction of required inventory (less capital tied up). Second, Anomaly Detection—the system notices when inventory looks 'suspicious' (e.g., theft or booking errors), as highlighted by Digital Magazin. Third, Assistance—chatbots that evaluate warehouse data in natural language ('Where is my delivery?'). The real game-changer is Consultative Intelligence that prevents errors through product understanding.

Not quite, but it's dying out. For 95% of retailers, cloud (SaaS) is the better choice due to flexibility, security, and interface currency. On-premise is only worthwhile for corporations with extremely specific security requirements or legacy infrastructure. The inability to leverage AI capabilities effectively is the main limitation of on-premise solutions going forward.

Implementation varies significantly by solution complexity. Simple cloud solutions like Pickware can be operational within days. Mid-market solutions like xentral or weclapp typically require 2-4 weeks for full setup including data migration. Enterprise solutions like SAP EWM can take 6-12 months for complete implementation. The key is choosing a solution matched to your actual complexity needs.

Real-World Applications: Beyond Traditional WMS

The evolution of warehouse management software connects to broader trends in business automation. Companies achieving the greatest efficiency gains are those integrating their WMS with customer-facing intelligence.

Consider how AI Employee 'Kira' handles customer inquiries about product availability and specifications—information that directly connects to warehouse data. Or how AI Product Consultation helps customers select the right products before ordering, reducing returns caused by incorrect selections.

The businesses seeing the strongest results combine intelligent warehouse management with smart customer interactions. When your AI Chat solution understands not just what customers want but what's actually in stock and compatible with their needs, you create a seamless experience that prevents errors before they happen.

This integration extends to social media inquiries and WhatsApp automation, where customers increasingly expect real-time inventory and compatibility information. The warehouse of 2026 isn't just a storage facility—it's an intelligent node in your entire customer experience ecosystem.

Implementation Reality: What They Don't Tell You

Most articles list features but don't explain how to actually set them up or the specific pains of migration. Here's what you should actually expect during implementation:

Common Implementation Challenges

- Data Migration Complexity: Historical inventory data often has inconsistencies that surface during migration. Budget extra time for data cleanup.

- Staff Resistance: Warehouse teams accustomed to existing processes need proper training and change management, not just software access.

- Integration Testing: Connections to shops and marketplaces work in testing but may behave differently under production load.

- Process Redesign: Often, existing processes need adjustment to leverage new system capabilities—don't just digitize inefficiency.

Success Factors for WMS Implementation

Companies that successfully implement modern warehouse software share common approaches:

- Start with process mapping: Document current workflows before selecting software

- Involve warehouse staff early: Those doing daily picking understand pain points best

- Plan parallel operation: Run old and new systems simultaneously during transition

- Define success metrics: Know how you'll measure improvement (error rates, pick times, accuracy)

- Budget for training: Software is only valuable if staff can use it effectively

The implementation phase is where many projects fail not due to software limitations but due to organizational factors. Companies like those using AI Employee Theresa have found that combining technology adoption with proper change management dramatically improves outcomes.

The Future: Warehouse Management 2.0 and Beyond

The days when warehouse management software was just a digital inventory list are over. In 2026 and beyond, software becomes the central nervous system of your commerce operations.

Competition will no longer be won solely through price or product, but through the reliability and speed of logistics. A system that 'only' manages is no longer sufficient. You need a system that understands and advises.

Whether you start with JTL, grow with weclapp, or automate with Mecalux—the step away from Excel and toward a professional warehouse management system is the most important step for your scalability. The question isn't whether to make this transition, but how quickly you can gain competitive advantage through intelligent warehouse operations.

For businesses ready to take the next step, combining modern WMS with intelligent customer interaction creates a powerful competitive moat. Explore how you can hire an AI employee to extend your warehouse intelligence to every customer touchpoint, or schedule a demo to see these capabilities in action.

Stop losing revenue to preventable errors. Discover how AI-powered intelligence can transform your warehouse from a simple storage facility into a competitive advantage that understands your products and prevents costly mistakes.

Start Your Free Trial