Have You Wondered Why Your Warehouse Overflows?

Have you ever wondered why your warehouse is overflowing, but your profits aren't growing at the same rate?

If you run a WooCommerce store, you know the scenario all too well: orders come in, excitement builds—and then the real work begins. Folding boxes, printing labels, reconciling inventory in your WooCommerce warehouse, and rushing to the post office. Eventually, you face the classic decision: Should I expand my warehouse or hire an external service provider?

But most shop owners overlook the biggest cost factor in their WooCommerce logistics: the return.

In this comprehensive guide (updated for 2025), we'll not only explore how to master your WooCommerce fulfillment technically and operationally. We'll go one crucial step further. We'll show you why efficient logistics doesn't begin in the warehouse—it starts in your shop's frontend, through intelligent, AI-powered consultation that prevents returns before they happen. This approach aligns perfectly with modern AI logistics strategy principles that forward-thinking merchants are adopting.

What Is WooCommerce Fulfillment?

Before diving deep, let's clarify the terminology. WooCommerce Fulfillment describes the entire order processing workflow after a customer clicks "Buy" in your WordPress shop.

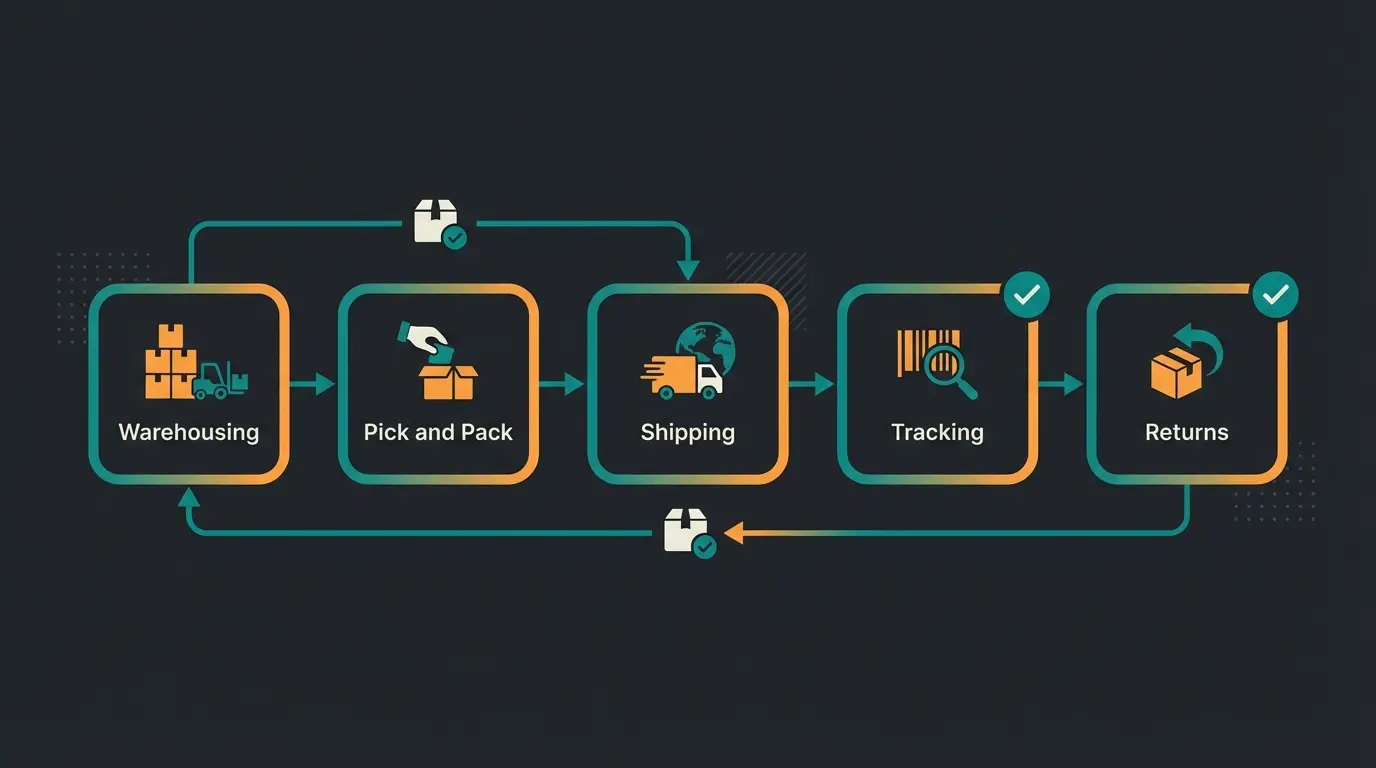

It's the operational backbone of your e-commerce business and encompasses five core areas:

- Warehousing: The physical storage of your products.

- Pick & Pack: Retrieving items from shelves and packaging them for shipment.

- Shipping: Handoff to courier services (DHL, FedEx, UPS, USPS, etc.).

- Tracking: Communicating shipment status to customers and back to WooCommerce.

- Returns Management: Receiving, inspecting, and restocking returned merchandise.

The Difference Between Warehouse and Fulfillment

While your WooCommerce warehouse (often managed through plugins or an inventory management system) refers to stock data ("How many red t-shirts do I have left?"), fulfillment is the action. Accurate warehouse data is a prerequisite for good fulfillment, but without efficient processes, even the best data won't help you succeed. Understanding this distinction is essential for implementing effective Shopware API automation strategies that connect your systems seamlessly.

The Strategy Decision: Self-Fulfillment vs Outsourcing

The most common question growing shops face: "Should I continue packing myself or hire a service provider (3PL - Third Party Logistics)?"

There's no right or wrong answer here—only what fits your current phase.

Option A: Self-Fulfillment (In-House Fulfillment)

You rent warehouse space, hire staff, and use tools like Billbee or JTL-Wawi to print labels.

- Advantage: You have 100% control. You can include a handwritten card with each package or perfect the unboxing experience.

- Disadvantage: Fixed cost risk. If you rent a warehouse for 1,000 packages but only sell 100, you still pay the full rent. Plus, it ties up massive amounts of your time.

Option B: Outsourcing (Fulfillment Service Provider)

You send your merchandise to partners like Zenfulfillment, byrd, or Lufapak. They store the goods. As soon as an order comes in through WooCommerce, it's automatically transmitted to the warehouse and shipped.

- Advantage: Maximum scalability. Whether 10 or 10,000 orders—you typically pay variable costs per shipment (pick & pack fee).

- Disadvantage: Less control over the package experience and dependency on your service provider's performance.

Decision Guide: The Comparison

| Criterion | Self-Fulfillment (In-House) | Outsourcing (3PL Provider) |

|---|---|---|

| Cost Structure | High fixed costs (rent, staff) | Variable costs (pay-per-order) |

| Control | High (unboxing, branding) | Medium (standard processes) |

| Time Investment | Very high (packing, organization) | Low (management & monitoring) |

| Scalability | Limited (space/staff) | Very high (peak loads possible) |

| Best For | Startups, niche products, custom items | Scaling shops, standard goods |

The Blind Spot: True Costs of Returns

Most articles about WooCommerce logistics end at shipping. But that's an expensive mistake. Germany's return rate is extremely high by international standards—and this affects any merchant shipping to German customers or operating in similar markets.

The Hard Numbers (2024/2025 Data)

According to Bitkom, German online shoppers return an average of 11% of their purchases. In the fashion sector, this rate often ranges between 26% and 50%, as reported by Spiegel and Retail News.

What does each return cost? A single return costs merchants an average of €5.00 to €10.00. For bulky items (furniture, home goods), these costs quickly climb to €20.00 or more, according to research from Händlerbund and EHI.

Overall average across all product categories

Apparel and shoes see the highest return rates

Average processing cost for standard items

Furniture and large goods return costs

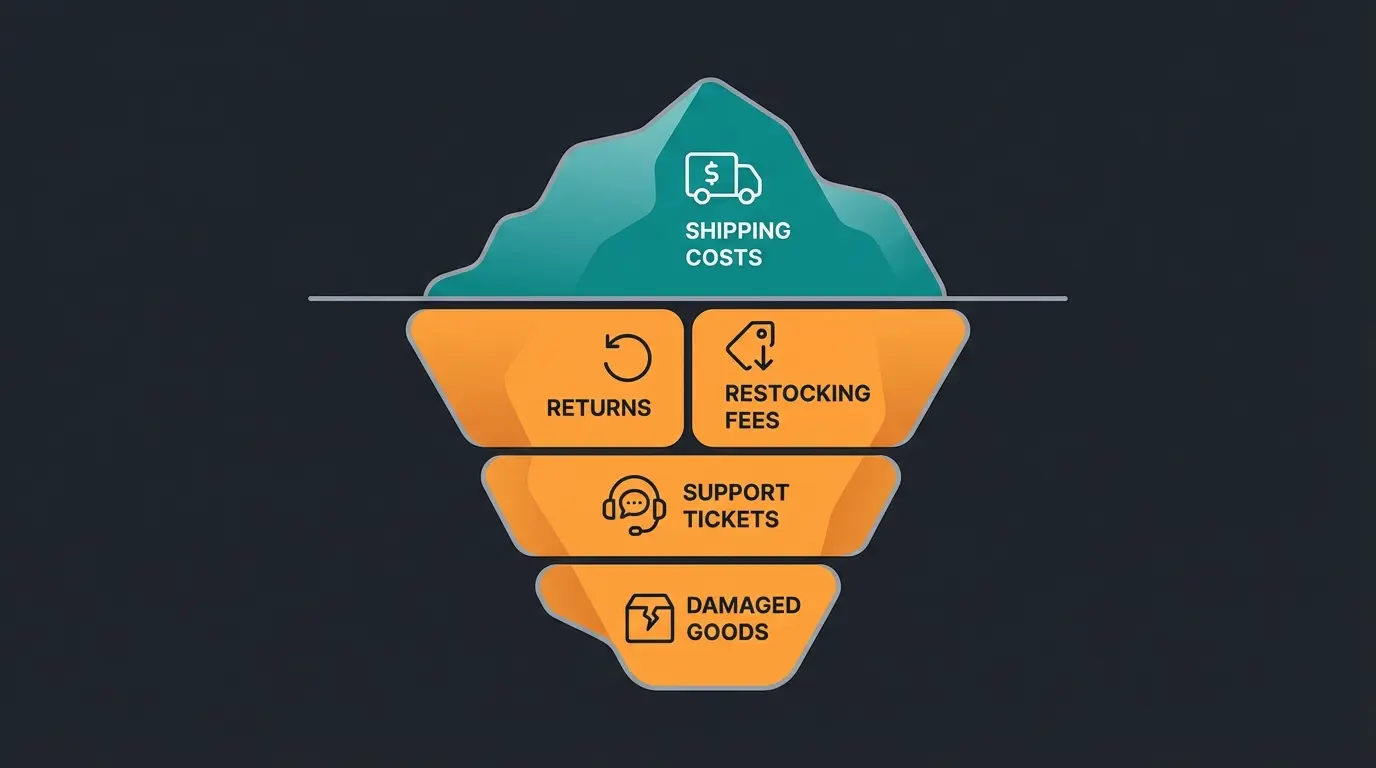

The Iceberg Model of Fulfillment Costs

Many merchants only see shipping costs (above water). But the true costs lurk beneath the surface:

- Shipping Costs (Both Ways): Often the merchant covers both directions.

- Value Depreciation: The item is no longer "new" (B-stock).

- Processing Costs: Unpacking, inspecting (quality control), repackaging, restocking. According to EHI studies, quality control is the biggest cost driver.

- Support Effort: "Where's my refund?", "I used the wrong return label."

Why Do Customers Return Products?

The reasons are almost always preventable:

- 67%: Size doesn't fit

- 56%: Item defective or damaged

- 50%: Doesn't match expectations

- 41%: Item doesn't match description or images

Here lies the real problem: Logistics has to pay for what went wrong in the shop frontend. This is precisely where AI prevention solutions can make a transformative difference.

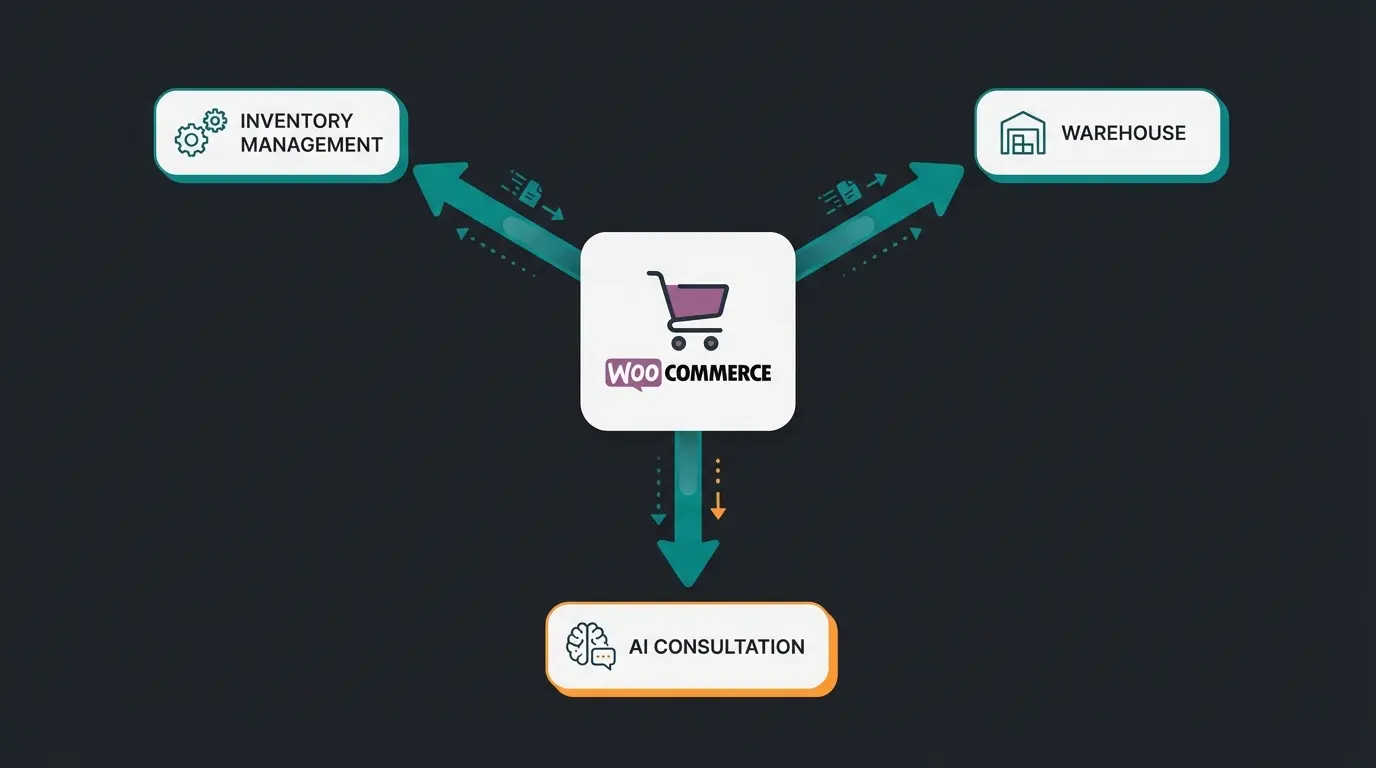

The Game Changer: How AI Consultation Relieves Logistics

Traditional logistics optimization means: Pack faster. Modern logistics optimization means: Prevent wrong orders.

This is where your Unique Selling Point comes into play. Instead of just optimizing the warehouse, smart WooCommerce shops deploy AI-powered product consultation (Conversational Commerce).

The Principle: Shipping Right vs Just Shipping Fast

Imagine having a digital salesperson who consults every customer in your shop before they add something to their cart.

Without AI: The customer is unsure whether the replacement part fits. They order Variant A and Variant B. They keep one, return the other.

- Result: Double shipping costs, one return, value depreciation.

With AI Consultation: The customer asks the AI assistant: "Does this part fit my 2020 model?" The AI analyzes the data and responds: "No, you need Variant C. Here's the link."

- Result: One order, one shipment, no return.

This is the foundation of effective AI product consultation that transforms customer interactions into confident purchases.

Visitor has product compatibility or sizing question

AI analyzes data and recommends the exact right product

Customer places order with certainty in WooCommerce

Order automatically transmitted to fulfillment system

Correct product shipped to satisfied customer

Happy customer keeps the product—no logistics overhead

Why This Works: Data and Facts

Studies show that implementing Conversational AI (chatbots and assistants) can reduce service costs by up to 30%, as documented by Cube Asia and Acuvate. Even more importantly: when customers are confident they're buying the right product, the probability of a return drops dramatically.

- Prevention: 74% of merchants view return prevention as a priority, according to Gabot. Detailed product information is the key—and AI can deliver this information interactively and personalized.

- Customer Satisfaction: Customers don't want returns. Returns are hassle. Good consultation that leads to the right product is the best service.

This approach represents the cutting edge of AI-powered e-commerce, where the shopping experience directly impacts operational efficiency.

Reactive vs Proactive Fulfillment Compared

Understanding the difference between traditional reactive fulfillment and AI-enhanced proactive fulfillment illustrates why this approach delivers superior results:

| Metric | Traditional Shop | AI-Enhanced Shop |

|---|---|---|

| Return Rate | 11-50% depending on category | Significantly reduced through pre-purchase guidance |

| Support Ticket Volume | High (sizing, compatibility questions) | Low (AI handles inquiries 24/7) |

| Customer Certainty | Low (guess and return) | High (confident, informed purchases) |

| Logistics Complexity | High (returns processing) | Streamlined (fewer reverse logistics) |

| Cost Per Order | Higher (return overhead built in) | Lower (optimized first-time fulfillment) |

The implementation of AI Customer Service systems transforms how merchants handle pre-purchase inquiries, directly impacting fulfillment efficiency.

Discover how AI-powered product consultation can slash your return rates and streamline your WooCommerce logistics operations.

Start Free Trial2025 Market Overview: Best Fulfillment Providers and Tools

If you decide to outsource or want to professionalize your internal logistics, you need the right partners. Here's an overview of the market.

Top Fulfillment Service Providers (3PL) for WooCommerce

These providers store your merchandise and ship it for you:

- [Zenfulfillment](https://zenfulfillment.com): Known for transparent pricing without hidden fees. Offers fast WooCommerce integration, as noted by GoodFirms.

- [byrd](https://getbyrd.com): Strong European network. Ideal if you want to scale internationally. Offers a modern dashboard, according to Bezos.ai.

- [Lufapak](https://lufapak.de): Experienced service provider, good for larger volumes and custom requirements.

- [Miller & Becker](https://millerbecker.de): Focused on scalability and branding options (custom boxes, etc.).

- DHL Fulfillment Network: The classic choice. Offers enormous reach and trust through the DHL brand.

Best Inventory Management Systems for WooCommerce

If you ship yourself or manage multiple channels (Amazon, eBay, shop), you need an inventory management system as the "brain" between WooCommerce and your warehouse.

- [Billbee](https://billbee.io): The favorite of beginners and medium-sized shops. Cost-effective, very intuitive, covers invoicing, label printing, and inventory synchronization. Not a heavy ERP—lean and effective, as detailed by SoftwareABC24.

- JTL-Wawi: The market leader in Germany. Free in the basic version but extremely powerful and complex. Ideal for merchants with high volumes and complex warehouse processes, according to Franz Sauerstein and GN2.

- [Xentral](https://xentral.com): Modern cloud-based ERP. Strong in automation and scaling, but more expensive and complex to set up than Billbee, as noted by Pulpo WMS.

For merchants also selling on Amazon, implementing AI consultation for Amazon integration can unify your multi-channel fulfillment strategy.

Cost Indicators: What Does Fulfillment Cost in 2025?

To help you calculate, here are rough benchmarks from current market analyses by Beckmann Systems, Warehousing1, and Büdel Lagerlogistik:

- Storage: approx. €8.00 – €15.00 per Euro pallet / month

- Pick & Pack: approx. €1.00 – €2.00 per order (plus surcharge per additional item)

- Shipping (National): approx. €4.00 – €6.00 (volume dependent)

- Returns Processing: Often flat rate approx. €5.00 – €10.00 plus refurbishment

Technical Integration: Connecting Shop and Warehouse

How does the order get from WooCommerce to the packer? There are two main pathways.

Path A: Direct Plugin Integration (For Small Shops)

You use plugins like Germanized for WooCommerce or direct shipping plugins (e.g., DHL for WooCommerce, Sendcloud).

- Process: Order comes in → You click "Create Label" in WooCommerce backend → Printer outputs the label.

- Disadvantage: With 50 orders a day, manual clicking becomes torture.

Path B: Inventory Management/Middleware (The Pro Approach)

WooCommerce sends data to a system like Billbee or JTL.

- Sync: Customer places order.

- Data Flow: WooCommerce transfers the order via API to the inventory system.

- Fulfillment: For self-fulfillment, the system creates a pick list and prints all labels in batch. For outsourcing, the system automatically forwards the order to the fulfillment provider.

- Feedback: Once the package is scanned, the provider sends the tracking number to the inventory system → System sends it to WooCommerce → WooCommerce sends the "Shipped" email to the customer.

Important: Your AI solution sits before this process. It ensures that the data generated in Step 1 (order) is correct. The best technical integration is worthless if the customer ordered the wrong product. This is where KI E-Commerce principles become essential for your overall strategy.

Checklist: The Perfect Logistics Chain

Use this checklist to audit and optimize your WooCommerce logistics.

Phase 1: Prevention (Frontend)

- ☐ Product Descriptions: Are dimensions, materials, and compatibilities clearly stated?

- ☐ AI Consultant: Is an intelligent consultant integrated that clarifies customer questions before purchase? (Reduces "order both sizes" behavior)

- ☐ Images: Are there high-resolution images and possibly AR functions?

Implementing a Consultative AI system addresses these frontend challenges systematically.

Phase 2: Processing (Backend)

- ☐ Automation: Are invoices and labels created automatically (e.g., via Billbee)?

- ☐ Inventory Synchronization: Is warehouse stock in WooCommerce always current (prevents overselling)?

- ☐ Provider Check: Do you annually review: Are my shipping rates still competitive? Would switching to a 3PL make sense?

Phase 3: Post-Purchase (After the Sale)

- ☐ Tracking: Does the customer receive proactive updates (not just "shipped" but "arriving tomorrow")?

- ☐ Returns Portal: Is there a simple digital portal for returns (instead of paper inserts) to digitally capture and analyze return reasons?

Building your store into an AI sales machine setup ensures all these elements work together seamlessly.

WooCommerce Fulfillment FAQ

WooCommerce fulfillment encompasses the entire order processing workflow from warehousing to delivery, including pick & pack, shipping, tracking, and returns management. It's crucial because efficient fulfillment directly impacts customer satisfaction, repeat purchases, and your bottom line. Poor fulfillment leads to negative reviews, high return rates, and eroded margins.

Consider switching to a 3PL provider when you consistently process 50-100+ orders per month, when packing and shipping consumes more than 20% of your time, or when you need to scale quickly without massive warehouse investments. The break-even point varies by product type, but most merchants find outsourcing more cost-effective once they reach consistent volume.

The most effective way to reduce returns is preventing wrong purchases in the first place. Implement AI-powered product consultation that answers customer questions before checkout, provide detailed product descriptions with accurate sizing charts and compatibility information, use high-quality images from multiple angles, and collect customer data to personalize recommendations. Studies show that confident buyers return far less frequently.

Expect to pay approximately €8-15 per pallet per month for storage, €1-2 per order for pick & pack, €4-6 for national shipping, and €5-10 for returns processing. Costs vary based on product size, volume commitments, and service level agreements. Always request detailed quotes from multiple providers and watch for hidden fees.

Integration typically happens via API connection or middleware. Use inventory management systems like Billbee or JTL-Wawi as the bridge between WooCommerce and your fulfillment partner. When an order is placed, data flows automatically to the warehouse. Once shipped, tracking information syncs back to WooCommerce and triggers customer notifications. Most modern 3PL providers offer direct WooCommerce plugins for seamless connectivity.

Conclusion: The Future of WooCommerce Fulfillment

WooCommerce Fulfillment in 2025 is far more than just moving boxes. It's a data-driven cycle that determines your shop's success.

While most merchants try to optimize their margins by switching shipping providers for a few cents, the real lever lies elsewhere: in the quality of the order itself.

If you want to sustainably improve your logistics, you need to address the problem at its root:

- Use modern tools (inventory management systems/3PL providers) to automate the physical process.

- Use AI-powered consultation to proactively prevent returns.

A package that doesn't get returned is the most profitable logistics service you can provide.

The comparison between traditional approaches and AI-enhanced strategies, similar to evaluating AI employees versus manual processes, reveals the transformative potential of intelligent automation in fulfillment operations.

Want to learn how AI can reduce your return rate and drastically cut your logistics costs? Discover our solution for intelligent product consultation that turns browsers into confident buyers.

Get Started Now